.ship floor .ship floor .floor construction .plate floor

Ship floor construction:

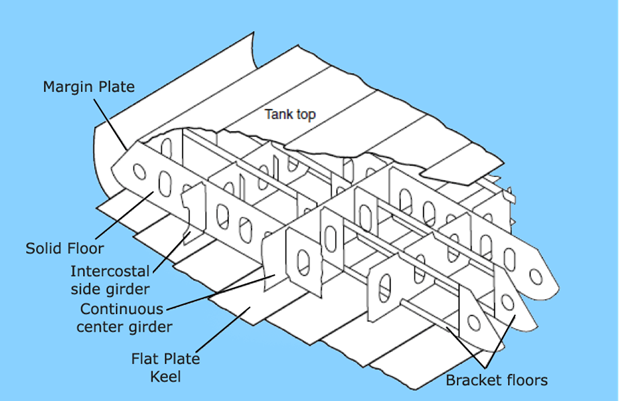

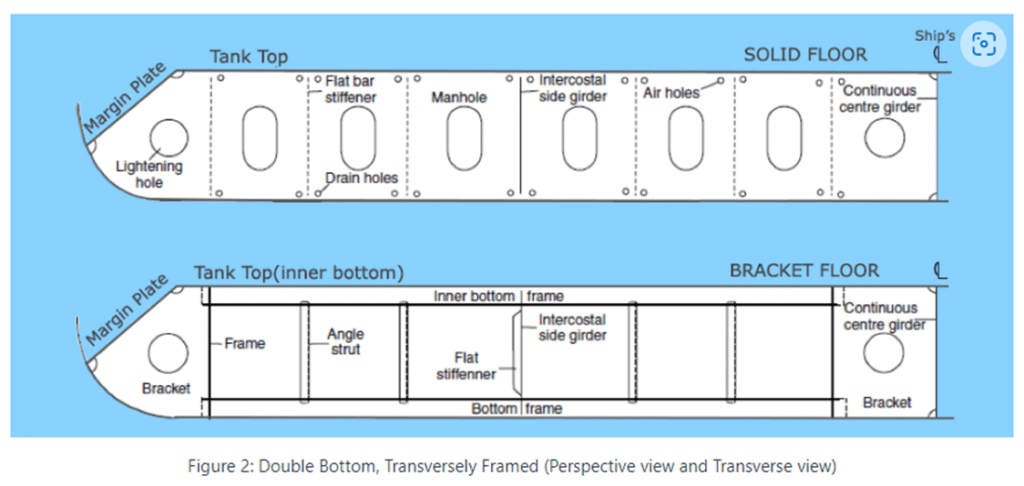

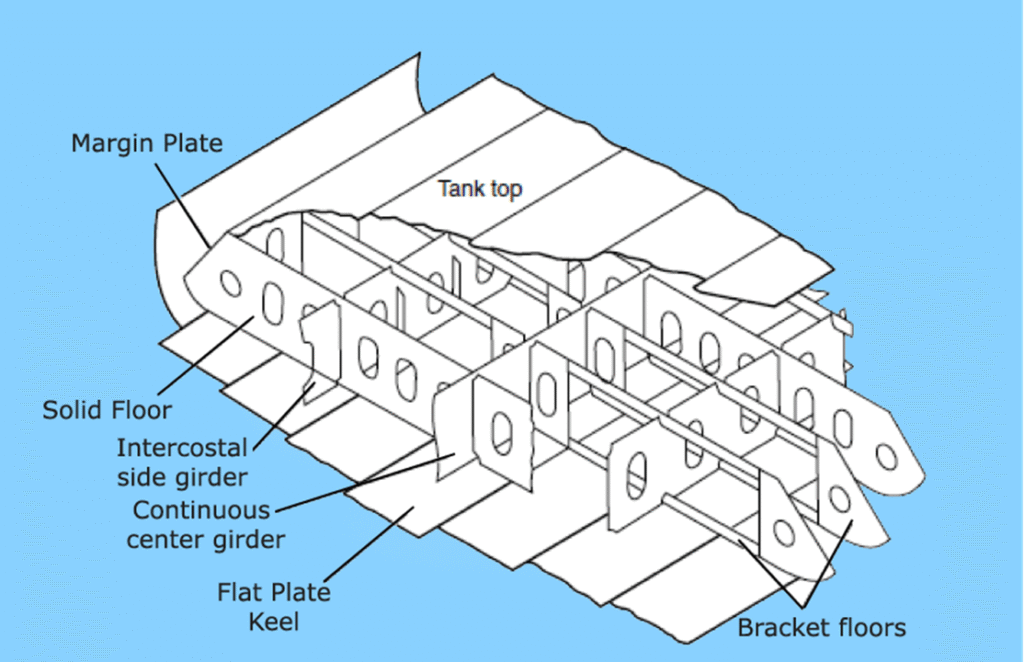

Double bottom, transversely framed floor construction:

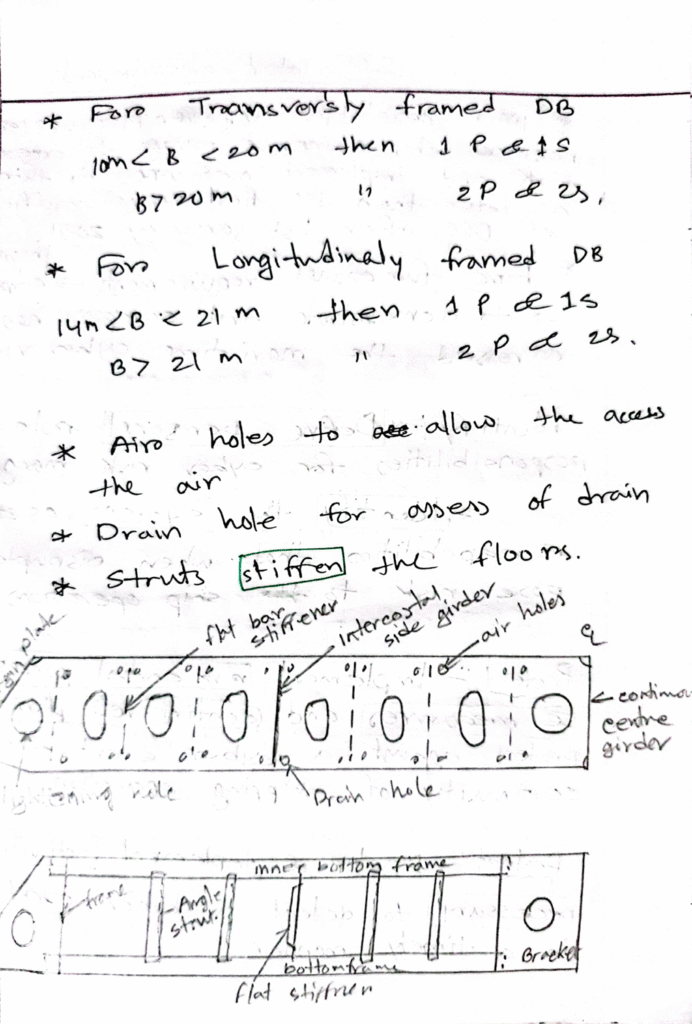

→this type of floor construction used in ships of length less than 120 meters.

→Vertical transverse plate floors are provided both where the bottom is transversely and longitudinally framed.

→Watertight and oiltight plate floors are provided → At the ends of bottom tank spaces and under the main bulkheads

→ These are made watertight or oiltight by closing any holes in the plate floor and welding collars around any members which pass through the floors.

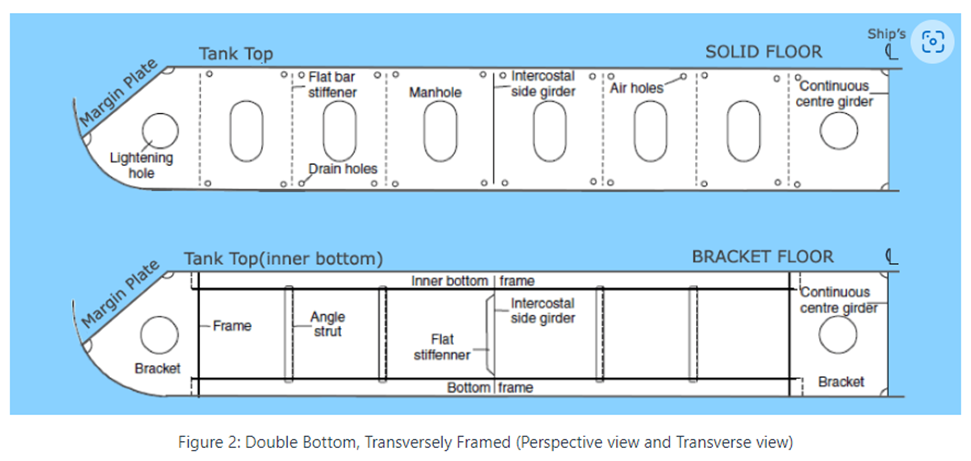

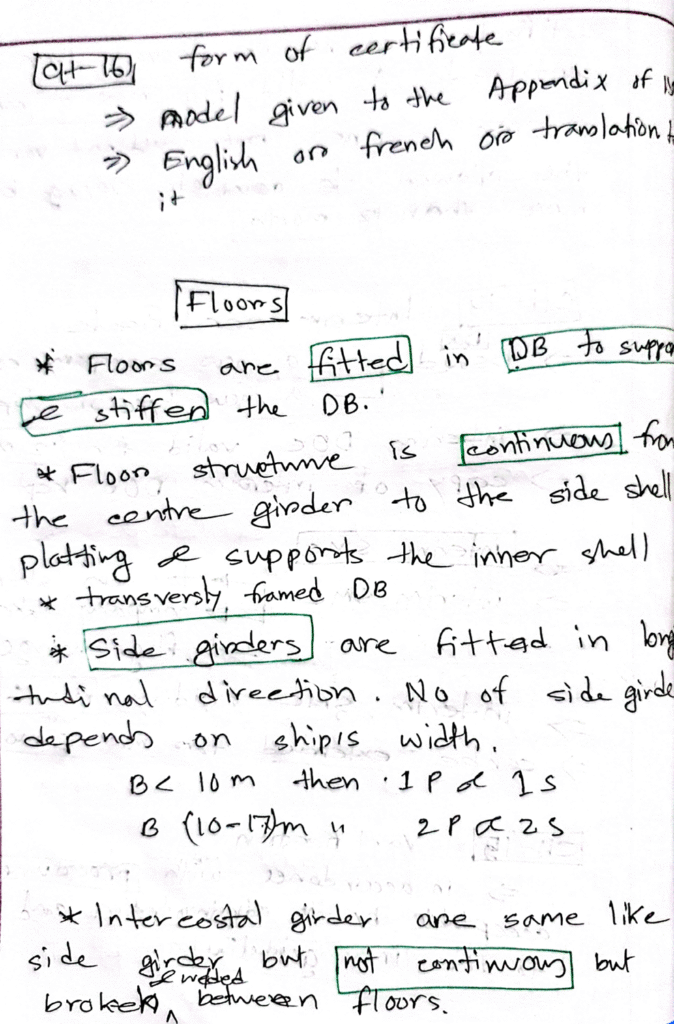

→The bracket floors form the transverse stiffeners at every frame, and

→solid plate floors are used at every 3 to 4 frame space, or 1.8 meters intervals, to strengthen the bottom transversely and support the inner bottom

→ intercostal side girders

→ run longitudinally fastening the transverse members of the floor,

→ it reduces the span of the plates.

→Side girders are continuous members,

→where there is an intersection between a plate floor and a side girder,

→the plate floor is cut and welded on both the sides of the girder

→ it is done to reduce the span of the plate floors,

→ the girders will act as supporting members to the plate floors.

→ Keels are flat plated.

→Intercostal girders or side girders, and plate floors

→ will have lightning holes at regular intervals to reduce the structural weight and

→will have flanged manholes to provide access.

→ Plate floors have drain holes to help drainage of liquids.

→Plate floors are

→further stiffened by flat bar stiffeners, and bracket floors, by angle struts to prevent warping.