The master solenoid is installed after the receiver, which is controlled by the control unit. In case of sudden stoppage of the compressor, the master solenoid also closes, avoiding the flooding of the evaporator with refrigerant liquid.

Thermostatic expansion valve

.tev .expansion valve .thermostatic expansion valve

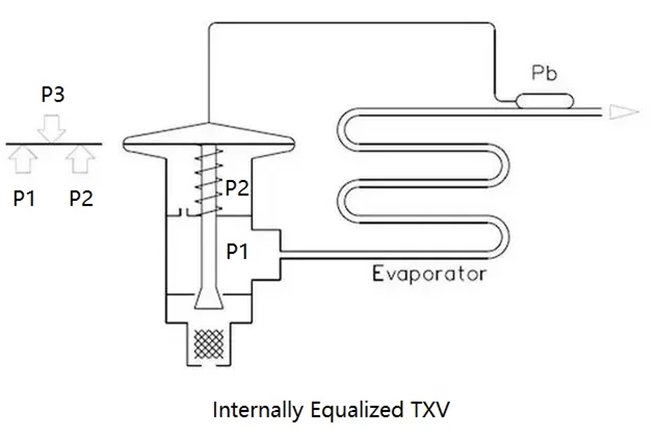

Thermostatic expansion valve maintains a constant superheat of the vapour refrigerant at the end of the evaporator coil, by controlling the flow of liquid refrigerant through the evaporator. Thus, its operation is based on the principle of constant degree of superheat at the evaporator outlet by controlling the flow of liquid refrigerant through the evaporator.

Thermostatic expansion valve consists of a needle valve and a seat, a metallic diaphragm, a spring and an adjusting screw .

In addition to this, it has a feeler or thermal bulb, which is mounted on the suction line near the outlet of the evaporator coil. The feeler bulb is partly filled with the same liquid refrigerant as used in the refrigeration system. The opening and closing of the valve depends upon the forces acting on the diaphragm.

When refrigeration load on the evaporator increases

If refrigeration load on the evaporator increases, it causes the liquid refrigerant to boil faster in the evaporator coil. The temperature of feeler bulb increases due to early vaporization of liquid refrigerant. Thus, the feeler bulb pressure increases and this pressure is transmitted through a small diameter tube (also known as capillary tube) to the diaphragm. The diaphragm moves downwards and opens the valve to admit more quantity of liquid refrigerant to the evaporator. This continues till the pressure equilibrium on the diaphragm is reached.

When refrigeration load on the evaporator decreases

On the other hand, when refrigeration load on the evaporator decreases, less amount of liquid refrigerant evaporates in the evaporator coil. The excess liquid refrigerant flows towards the evaporator outlet, which cools the feeler bulb. Due to this, the feeler bulb pressure decreases due to decrease in its temperature. The low feeler bulb pressure is transmitted through the capillary tube to the diaphragm and moves the diaphragm in upward direction. This reduces the opening of valve and thus, reduces the flow of liquid refrigerant to the evaporator. The evaporator pressure decreases due to reduced quantity of liquid refrigerant flowing to the evaporator. This continues till the evaporator pressure and the spring pressure maintains equilibrium with the feeler bulb pressure.

faults:

High suction temperature (superheat) caused by the lack of insulation on the suction, or by too small opening of expansion valve and hence the admission of too little liquid to the evaporating coils.