.rudder

Rudder types:

→Balanced Rudder

→Semi-balanced Rudder

→Unbalanced Rudder

The choice of rudder type depends on

→the shape of the stem,

→the type of vessel,

→the size of the rudder required and

→the steering gear available.

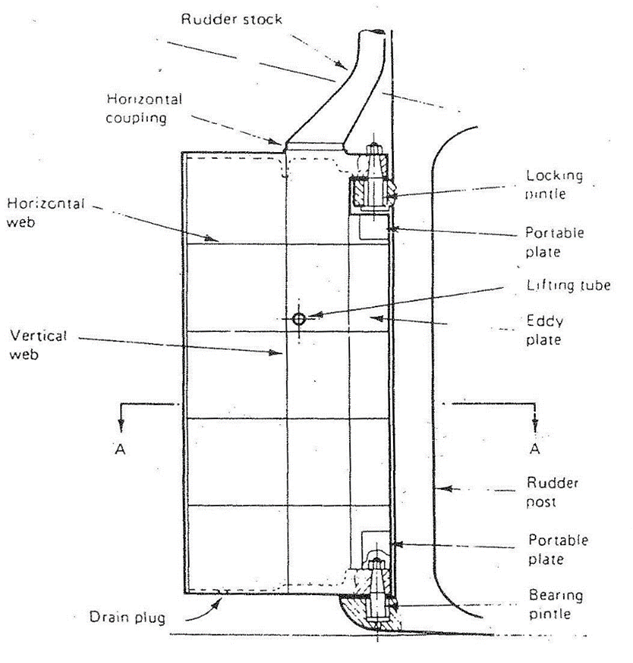

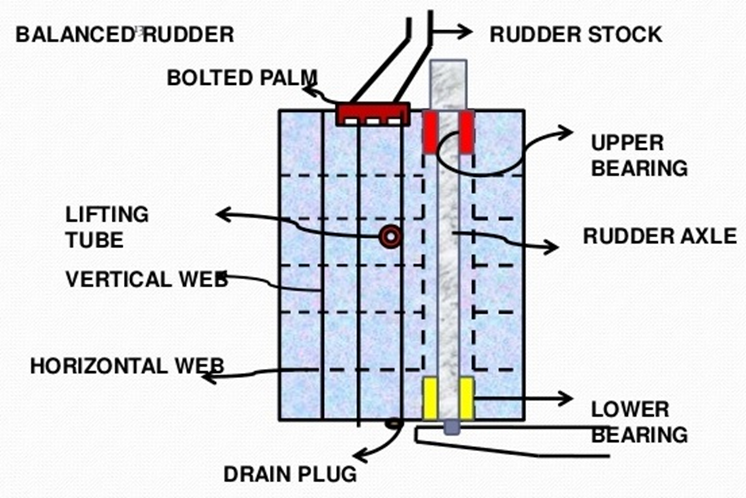

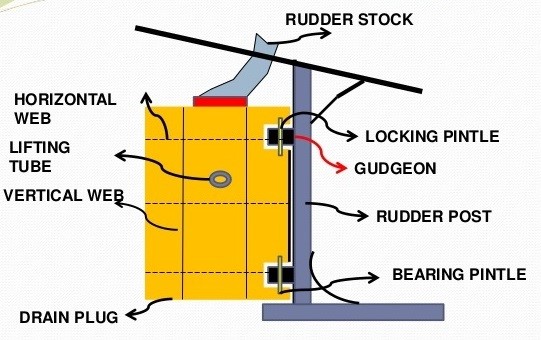

Parts of rudder:

- rudder stock

- rudder coupling

- rudder blade (rudder body)

- stem post with gudgeon

- pintles (upper and lower)

- rudder carrier bearing and g

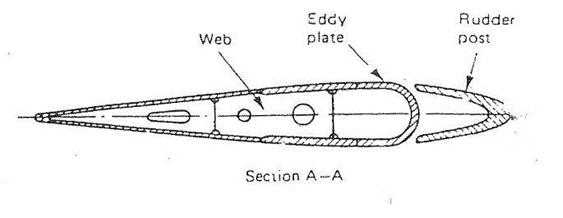

Balanced rudders or spade rudders:

This rudder has 20-40% of the area forward of the stock, similarly there is no torque on the rudder stock at certain angles, this type of rudder is called balanced rudder. The axis of the rudder is placed near to the center of gravity, so torque required to move the rudder will be very less.

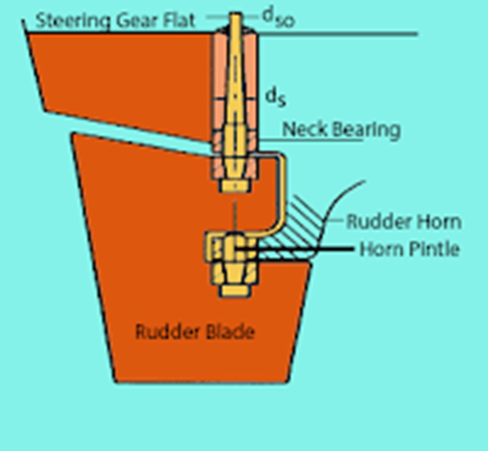

Semi Balanced:

→ A rudder with 20% of its area forward of its stock is called semi balanced rudder.

→ It is often found in twin screw ships.

→ it has fixed structure in upper half.

→ upper half is unbalanced.

→ lower half below the fixed structure is balanced

Unbalanced Rudder:

→A rudder with whole of its area aft of its stock is called unbalanced.

→ number of pintles fitted depends on the strength consideration.

→ torque required to move the rudder is very high.

Possible damages on rudder:

1. Fractured and loose coupling bolts

2. Loose Nut

3. Wear (excessive bearing clearance)

4. Fractures in way of Pintle cutout

5. Fractures in way of removable access plate

6. Fractures

7. Erosion

8. corrosion

What to look for in dry dock:

.rudder dry dock

→ deformation

→ fracture

→corrosion, erosion

→ clearance

Types of Works and Repair:

→Measurement of pintle clearance (the closing plate may have to be removed). Other clearances which are also taken are the jumping and the emergency carrier clearances.

→ Removal and replacement of rudder’s gland to renewal of rudder packing in the transom space.

→Disconnection of steering gear tiller or rotary vane and jacking up of rudder to inspect the stock steady bush.

→ Unshipping of rudder into the dry dock for survey/examination and repairs.

→Air test to check for leaks in rudder body. Repairs on damaged rudder body if any.

→Welding of erosion pits and wasted seams, replacement of zinc anodes.

→Repairs on damaged rudder stock.

→Repair on rudder couplings holes and bolts. Repair of sealing cement. Repair on rudder pintles and pintle bushes.

→Repair of pintle gudgeons

→ Common defects are wear, corrosion, twisting, cracks bending and fracture.

→Corrosion damage is observed mainly where the cylindrical part widens into the flange.

→Wear and corrosion can be rectified by means of deposit arc-welding with subsequent machining.

→ If cracks are found, then they are ground off and repaired by arc-welding.

→ Twisting and bending of the stock impede the normal working of the whole steering system. Too much twisting or bending requires a replacement of the stock. If slight bending, then a straightening force is applied by means of a hydraulic press.

Repairs of rudder coupling:

The rudder coupling is subjected to similar bending stresses and twisting stresses as the rudder stock.

These stresses give rise to fatigue of the coupling, bolts.

A coupling defect that may occur is the opening of the horizontal coupling at ‘the forward edge. This could result in corrosion of the flanges of the coupling as well as loosening of the bolts.

The situation could easily be aggravated by the weight of the rudder hanging by the coupling bolts. Repair could be affected ty building up the flange by means of welding and machining smooth. The bolt holes are then bored by a portable boring machine and new fitted bolts are then replaced.

Repairs on gudgeon:

The alignment of the upper and lower gudgeons are first checked by means of Laser or using piano wire which is tensioned to ensure that it is in a straight line.

Any misalignment discovered is then accurately recorded.

One method of repair is to build up the gudgeon by welding and then machining the diameter by a portable boring machine.

This method may prove to be difficult if the portable boring machine is not designed to bore taper accurately which can result in tedious fitting of the gudgeon. An alternative way to carry out such repairs is to fit a separate step-bush into the gudgeon which has been bored with a step as shown.

After fitting the step-bush into the gudgeon, it is further welded onto the forging.

The stern frame gudgeon, where corrosion damages are common, is also repaired the same way.

Clearances in rudder:

Jumping clearance

Pintle clearance

Rudder carrier bearing clearance

Tests of after repair:

At the completion of the repairs, the rudder system is reassembled and function tests are carried out to ensure satisfactory operation before undocking.

If any work was done on the rudder body, it should be tested by compressed air to an equivalent pressure head of 2.45 m above the top of the rudder.

Other tests include swing the rudder from one extreme position to the other

Why Rudder Angle Limited to 35 Degrees?

- Beyond 35-degree rudder efficiency is reduced due to formation of eddies on the back of rudder as the flow is no longer streamlined. This is called stalled condition.

- The maneuverability does not increase beyond 35 degree, but rudder torque increases and ship’s turning circle increases.

Why Steering Test Rudder angle 35 degree to 30 degree?

- So that the point at which it is reached can be exactly judged as it crosses 30 degree.

- As hunting gear puts pump stroke to zero, the rudder movement slows down progressively as it approaches 35 degrees.

Why Astern Turning Moment much less than Ahead ?

- The propeller thrust adds to the force on the rudder when going ahead, but in astern that thrust is lost.

- The pivoting point (point about which ship turns) shifts aft to 1/3 rd the length from aft. This reduces turning moment greatly.