.fo properties .fop .fuel oil properties .fueloil properties

FO properties, Consequences & Adjustments to use the fuel

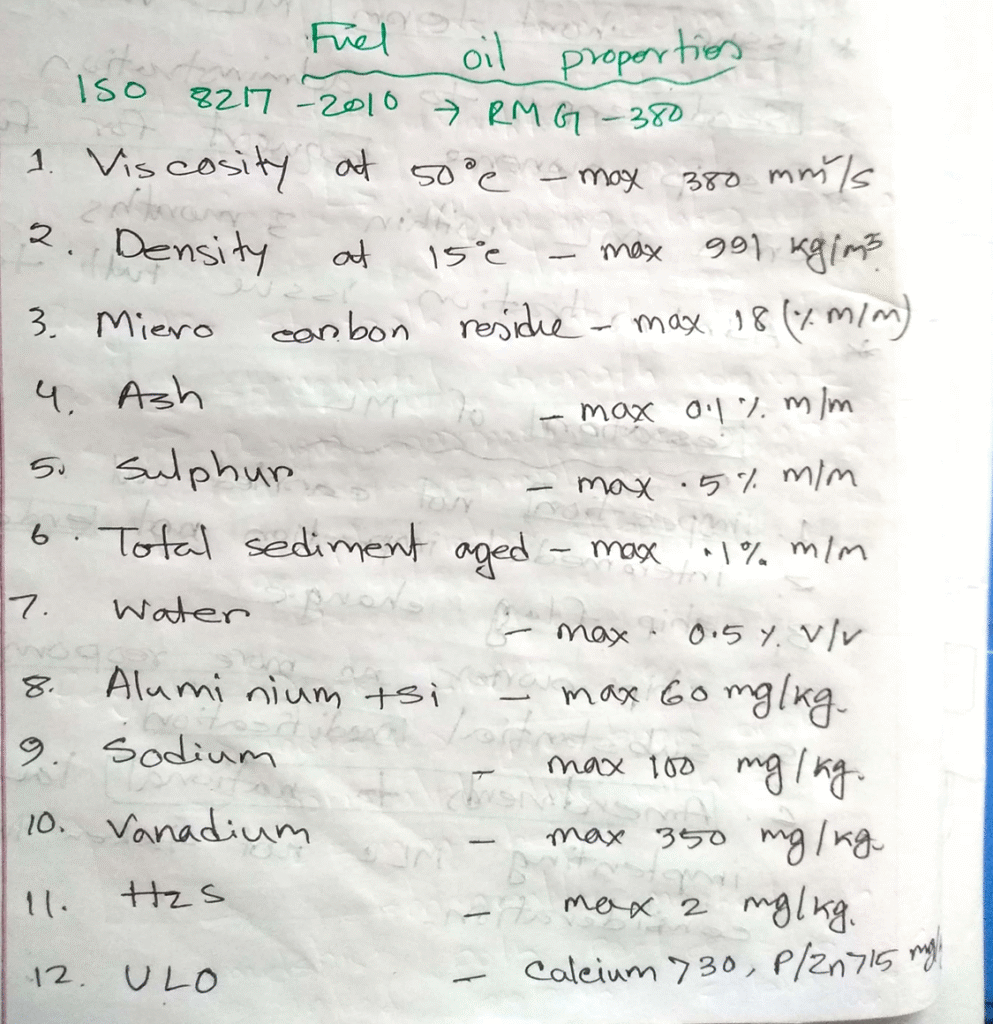

Density:

991 kg/m3

Consequences:

- Check the purifier on board.

- If it can handle up to 1010 kg/m3, then no problem. If it is conventional type (can handle up to 991 kg/m3) then interface may be shifted outwards & possibility of oil leaks through water outlet

Adjustment:

- Check nomogram, accordingly, select a smaller diameter of gravity disc.

- Maintain purifier operating temperature around 95-98◦C

Viscosity:

380 cSt

Consequences

- Ignition delay & after burning may occur.

- Impingement may occur

Adjustment:

- To obtain correct viscosity of 12-15 cst , the fuel injection temperature needs to be increased.

Water:

Max 0.5%

- If it is high then,

Consequences:

- Microbial degradation.

- Affect proper combustion.

- Water reduces the calorific value & increases SFOC.

- May not be good for cylinder oil film formation.

Adjustment:

- Frequent draining of settling/service tanks

- by proper purification

Carbon residue:

18% of total volume

- found in soluble form.

Consequences:

- Deposit on piston ring groove and fouling of T/C inlet grids, nozzle rings & turbines blades.

- Increase soot formation at EGE.

Adjustment:

- Increase the frequency of T/C grit washing.

- Increase the frequency of soot blowing & water washing of EGE.

- Increase the frequency of scavenge & under piston space cleaning.

- Inspection for scuffing at every opportunity.

Sulphur:

- After 1st January 2015, the ECA limit is 0.1%.

- After 1st January 2020, the Global limit is 0.5%.

Adjustment:

Ensure the TBN of the cylinder oil is suitable for low sulphur oil.

Ash

- Max 0.1% m/m , mostly found in insoluble form.

Consequences:

- Ash causes abrasive wear in liner and fuel pump.

- Scuffing & injector atomizing holes enlargement.

- Deposit on piston ring grooves, fouling of T/C inlet grids, Nozzle rings & turbine blades increased

- Increase soot formation at EGE.

Adjustment:

- Operate the centrifuges in series as purifier & then clarifier.

- Operate the centrifuges at optimum throughput. (5-10% above the consumption)

- Reduce the interval of de-sludging.

- Reduce the flushing interval of back flushing filters.

- Increase the frequency of all fuel filters cleaning

Vanadium:

Max 350 mg/kg. Found in natural form.

If it is high then,

Consequences :

- Known for its high temperature corrosion

- Combines with sodium to form a molten paste at temp around 500◦C.

- Leave sticky deposits on the exhaust v/v, piston crown, cylinder head, T/C.

Adjustment:

• Maintain exhaust temperature below 500◦C

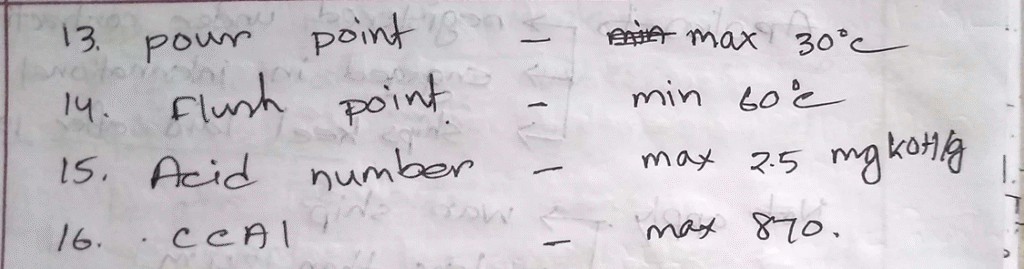

Flashpoint:

→Min 60 degree Celsius as per SOLAS, for emergency generator 43 degree celcius

Adjustment:

- Fuel oil temperature should not exceed 160◦C ( 170°C-10°C=160°C)

- Flashpoint should be minimum 60°C as per SOLAS. Reject if flashpoint value is lower than standard value

Pour Point:

Min 30 degree celcius

Adjustment:

- Maintain bunker tanks temp above 30°C(20+10)

Aluminium + Silicon:

Max 60 mg/kg

Consequences:

- Abnormal wear of fuel p/p plunger & barrels.

- Scuffing & injector atomizing holes enlargement.

- Associated with abrasive wear (as hard as diamond)

- Increase liner and piston ring wear

- Piston ring grooves deposits and fouling of T/C inlet grids, Nozzle rings, & turbine blades increased.

Adjustment:

- Operate the centrifuges in series as purifier & then clarifier.

- Operate the centrifuges at optimum through put. (5-10% above the consumption)

- Reduce the interval of de-sludging.

- Reduce the interval of back flushing filters.

- Increase the frequency of all fuel filters cleaning

Total sediment (aged):

Max 0.1% m/m, This related to ageing and blending of oil If it is high,

Adjustment:

- Consume this bunker first.

- Operate purifiers and de-sludge regularly.

- Try to keep in circulation as often as possible

Zinc, Phosphorous, Calcium: (ULO)

Calcium max 30 mg/kg

Zinc max 15 mg/kg

Phosphorus 15 mg/kg

Consequences:

Formation of deposits will increase

CCAI (Calculated Carbon Aromaticity Index):

Max 870 .

CCAI [1]determines the ignition quality of residual fuel oil although scientifically not proven. If high

Consequence:

- Higher CCAI determines lower ignition quality of fuel

- CCAI value determined from density and viscosity of fuel

- CCAI value more than 870 is unacceptable, indicates low ignition quality of fuel, leads to ignition delay

- After burning

- Low peak pressure

- High exhaust temp

- Lower power output

Adjustment:

Advance VIT

Acid number:

Max 2.5 mg KOH/g

Above limit and presence of inorganic acids.

Adjustments:

- Slightly increase the cylinder lubrication to neutralize the presence of acids.

Hydrogen sulfide:

Max 2% mg/kg . If it is high,

Consequences

- Tests to be carried out for human safety in the vicinity of the fuel tanks and vent

- Also contributes to acidity

- It is a colorless gas having foul odor of rotten eggs; it is heavier than air very poisonous, corrosive, flammable, and explosive.

Sodium:

Max 100mg/kg ,

Consequences:

• Suspect sea water contamination

• Risk of high temperature corrosion

Adjustment:

- Frequent draining of settling and service tank

- Increase T/c grit washing frequently

Maintain exhaust temp below 500◦C

Acids:

Organic acids: Acids derived from plants and animals are called organic acids.

Example– Citric acid in lemon and oxalic acid in tomato.

Inorganic acids: Acids derived from minerals present in the earth’s crust are called inorganic acids.

Example: Sulphuric acid and nitric acid

Effect of high and low viscosity of fuel oil

Too high viscosity leads to poor atomization, bigger droplet size, higher penetration causes impingement, resulting in incomplete combustion.

However, too low fuel viscosity may cause mechanical problems in engine use as leaking from the nozzle sealing and the fuel pump system. Generally, fuel oil viscosity is regulated between 10-15 centistrokes at 50 degree Celsius.

[1] CCAI is the ratio of the fuel which indicates ignition quality because ignition directly depends on the Aromatic Content in the fuel