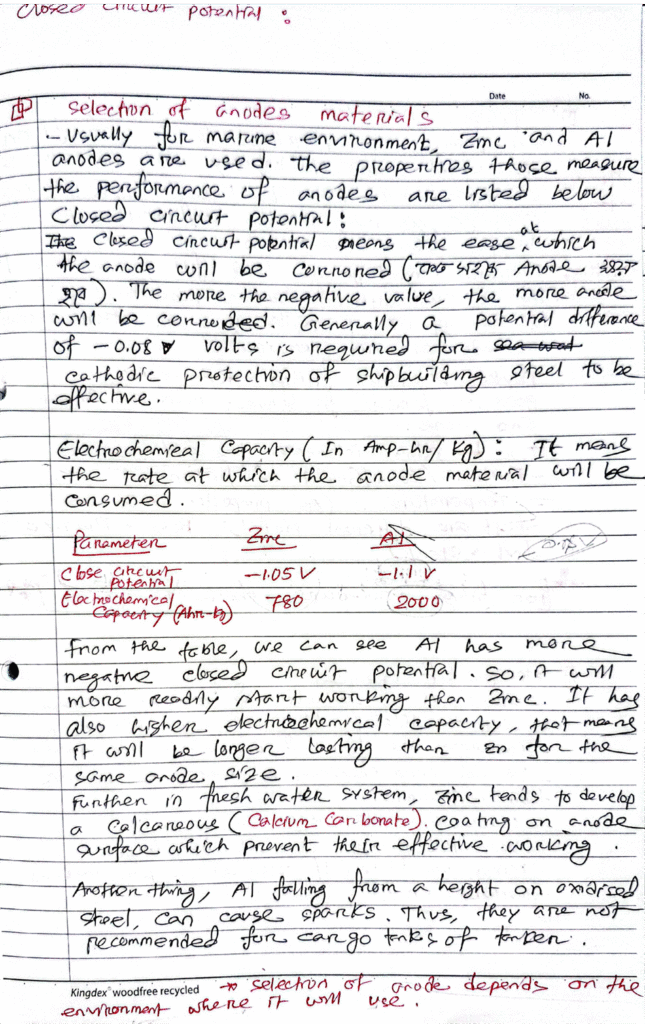

.anode types .anodes .zinc anode .aluminium anode

Commonly used anodes are Zinc, Aluminium, Soft iron, Magnesium

Advantages of aluminium anodes

Weight: Aluminium is significantly lighter than zinc, by a factor of 2.5. Al anodes are lighter to ship and to fit.

Capacity: The electrochemical capacity is more than 3 times higher than of the same mass of zinc (we can protect more with less).

Driving voltage: Aluminium anodes has a relatively high driving voltage. This means that it provides better distribution of the current, compared with zinc.

Environment: Aluminium anodes carry a better environmental footprint than zinc anodes. Aluminium anode alloys do not contain cadmium, which is harmful to the marine population.

Cost: Aluminium anodes are less expensive, considering the significantly reduced weight requirement compared with zinc.

Advantages of zinc anodes

Availability: Traditionally used by the maritime industry, hence zinc anodes are widely available.

Geometry: Zinc anodes can be produced in rather complex geometry, as opposed to aluminium. This is particularly important for slender designs, such as rope guard anode rings.

No restrictions for use in tanks: Zinc anodes are not subject to the same class restrictions as aluminium for use in tanks with possible explosive atmosphere.

The anode surface corrodes more evenly: Zinc anodes tend to dissolve more evenly and completely; while typical aluminium anodes erode unevenly with visible “craters”.

Soft iron anode:

Soft Iron Anode

It’s mostly used for the protection of copper alloys of heat exchanger, freshwater facility, desalination plant (evaporator, brine heater) and condenser (used for marine and platform).

Magnesium anode:

It is mostly used in fresh water systems.