Bearing Clearance Check:

.bearing clearance .bc check

Before undertaking any work on the engine, the safety check should be carried out:

- Take Permission to immobilize engine.

- Risk assessment should be carried out.

- Work permit to be taken.

- Starting air shut off and locked off.

- Open the indicator cock.

- Engine cooled down sufficiently to allow L.O pump to be shut down.

- Check that no one is working on the vicinity of the shafting.

- Take propeller clearance from bridge.

- All lifting gear, shackles etc checked for defects and check they are within certification.

Tool box meeting should be carried out, only the person in charge of operation is to operate the turning gear.

Bearing area need need to give particular attention

- Bottom half of the cross-head bearing

- Top half of crank pin bearing

- Bottom half of main bearing

Main Bearing Clearance:

.main bearing clearance .mbc

There are various types of methods adopted by different marine engine manufacturers to measure the clearance of main bearing of marine engine.

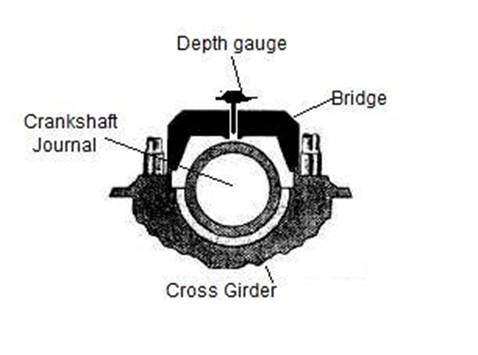

1) Bridge with Depth Gauge

This method is used in SULZER 2 stroke marine engines where the bearing ‘s shell is removed along with the keep (the bearing shell is lined with the keep). After that a bridge is fitted over the top of journal pin, from port to starboard, making a bridge over the crankshaft with two ends supported on the cross girder.

A simple vernier type depth gauge is then inserted in the hole provided on the bridge and the scale of depth gauge is rested on the crankshaft pin. The total depth on the scale is measured and compared with the previous reading and the reading in the manual for calculating the wear down of bearing.

In old model SULZER engines, a collar is provided in the bearing shell along with a small hole. Thus, without removing the keep, the bridge is fitted adjacent to the keep and the depth gauge is used from the hole provided in the shell to measure the shell wear down.

2) Bridge With Feeler Gauge

In some engines, after removing the shell and the keep, the bridge is installed on top. Also, in place of depth gauge, a feeler gauge is used to measure the clearance between the journal pin top and the bridge bottom. The bridge used here is different in terms of height and the gap between the pin and the bridge is very less

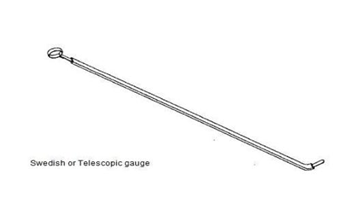

3) Telescopic or Swedish Feeler Gauge

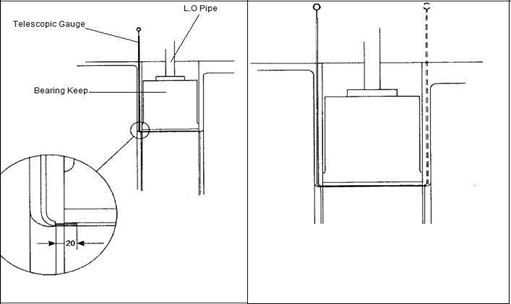

In engines like MAN B&W, this is the most common method used to measure the bearing clearance of the top shell. In this method there is no need to remove any connection or keep for measuring the clearance.

The telescopic gauge is inserted between the gap of the crank web and the bearing keep. When the tip reaches the shell top, the feeler is inserted between the shell and the pin to check the clearance.

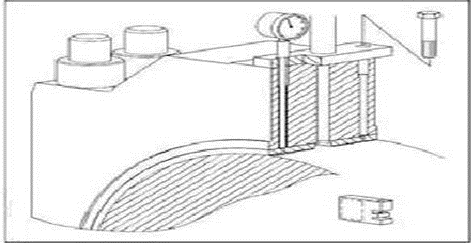

4) Dial type Depth Gauge

This method is used in new MAN B&W engines (SMC-C) which does not require the top keep to be removed. The lube oil pipe connection screw hole is in the bearing keep which can be accessed from the hole on the bearing shell.

The dial gauge is inserted in this screw hole and the reading is taken as the clearance for upper shell.

5) Lead wire – The Traditional Method

This is a traditional method and to be used when no other alternative or tools are present. In this method, lead wire is inserted at different positions between bearing and pin. The bearing housing is tightened. Ensure not over squeezed the wire more than 1/3 rd of original diameter.