.thrust bearing

Article link: https://www.marinesite.info/2013/12/thrust-bearing.html

- The thrust from the propeller is taken up by the main thrust bearing, which transmits the thrust to the ship’s hull and causes the ship to be propelled in the direction of the thrust.

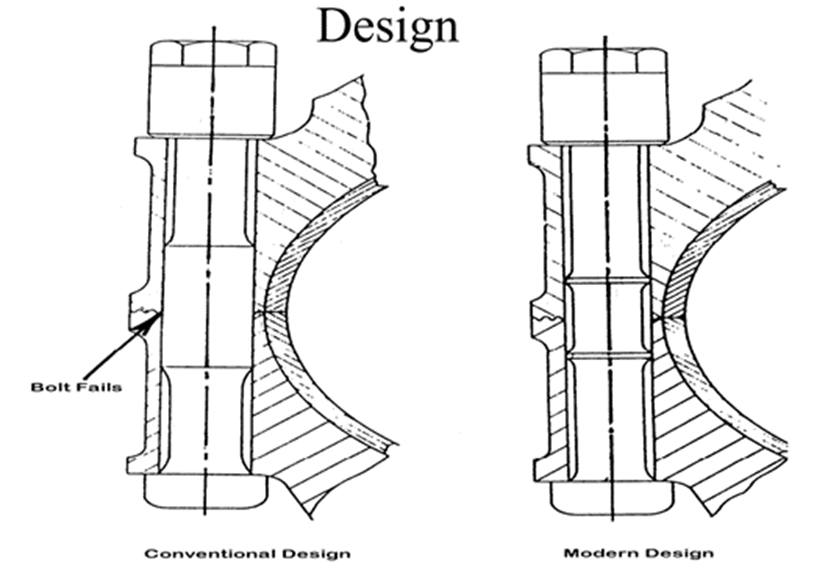

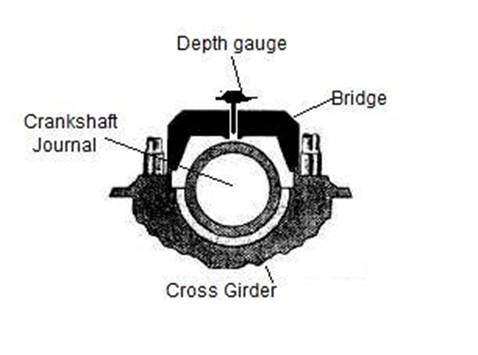

- The thrust bearing is always fitted at the aft end of the main engine crankshaft. The main thrust bearing controls the correct location of the crank pins relative to the center of the cylinders.

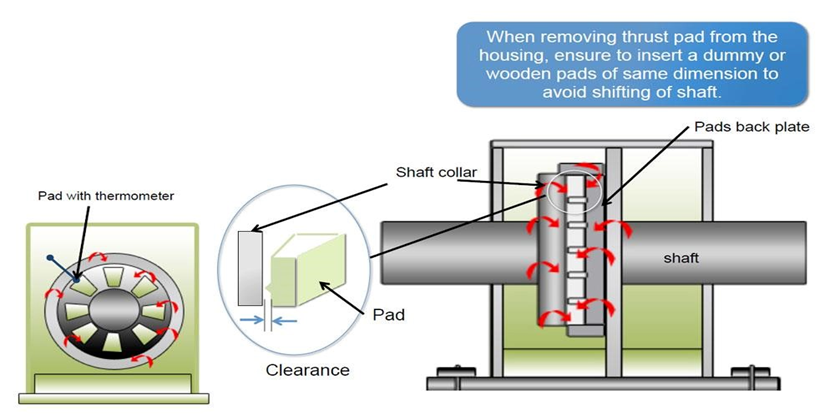

- In propulsion machinery, the thrust bearing most commonly used is tilting-pad type.

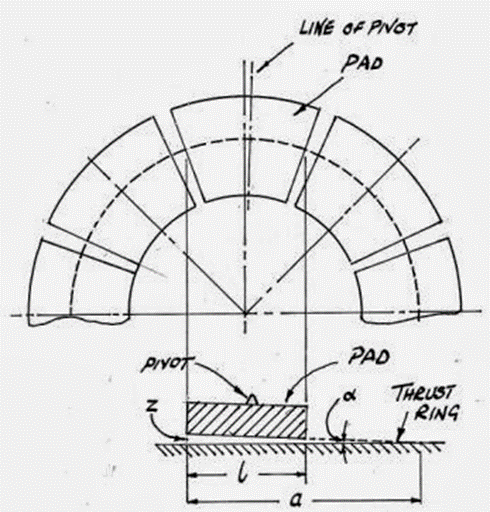

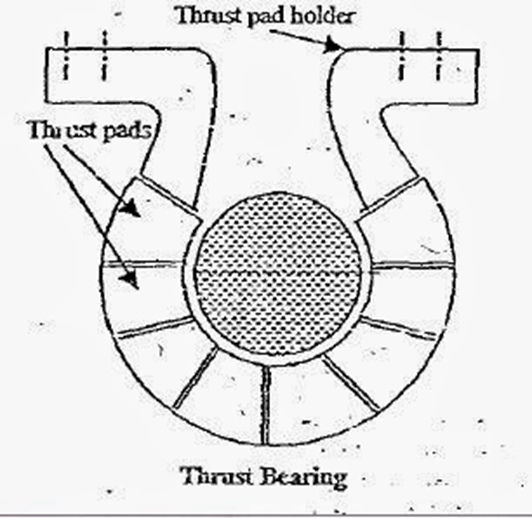

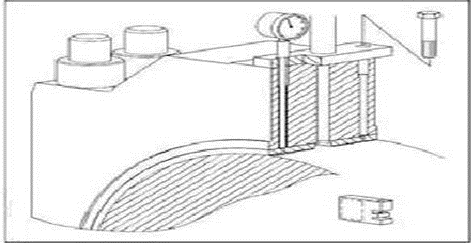

- In tilting pad type of bearing a thrust collar is forged integrally with the thrust shaft. on the forward and aft side of the thrust collar, the thrust pads are fitted.

- The thrust pads are lined with white metal and face on to the finally machined and polished surface of the thrust collar. The back of the pad has a radial ridge, which forms a fulcrum on which the pad can tilt. The tilting fulcrum on the back of the pad comes in contact with a solidly constructed housing. The housing is rigidly held in the thrust bearing casing.

- this type of bearing builds up an oil pressure between the white metal face of the thrust pad and the thrust collar when the shaft revolves. The oil pressure is due to the formation of an oil wedge, which can build up only when the thrust collar is supplied with the oil and is revolving. As the pad is able to tilt it becomes self-adjusting to the shape of the wedge.

- The thrust acting on the thrust collar is balanced by the oil pressure created by the tilting pad and thus transmitting the thrust to ship hull via tilting pad and housing.

- The radial ridge on the back of the pad, which becomes the fulcrum for the tilting action is often made off center. If the thrust pads are viewed from the top, the tilting point is always from the center moving in the direction of rotation of the collar.