.trt .tie bolt tightening .tbt

Initial preparation:

- Permission must be granted to immobilize the engine

- Spare & tools must be checked

- Conduct tools box meeting

- Hydraulic jack or tools used must have valid calibration certificate

- Risk assessment with work permit to be done properly

Preliminarily work:

- Clean the tie rod properly and carefully before inserting into position

- The lower nut of the tie rod is screwed on.

- Clean the seating surface for intermediate ring and the upper nut.

- Place intermediate ring and screw upper nut on the tie rod.

- Fit the ring screw into the tie rod and lift carefully till the lower tie rod nut seats firmly.

- In this position tighten the upper tie rod nut with tommy bar until it is firmly seated on the intermediate ring.

- Separate lifting tackle from the rod and remove ring screw.

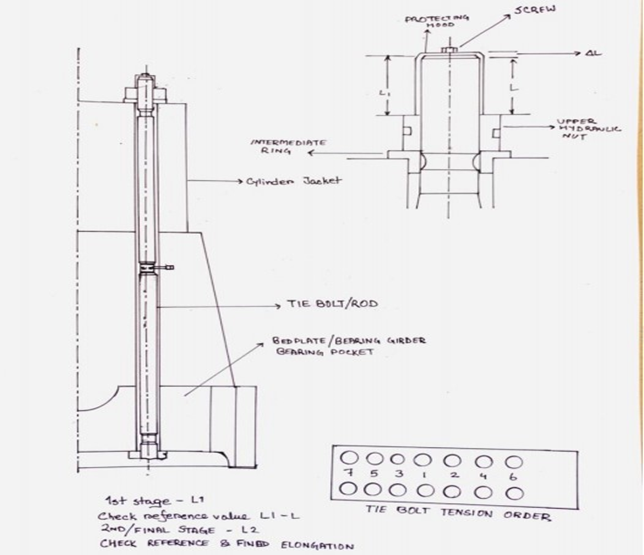

Working sequences for tensioning:

- Measure distance ‘L’ for all tie rods and record them.

- Mount pre tensioning jack on the two tie rods place opposite to each other a/a, the lower part of the cylinder jack must rest on the intermediate ring.

- Connect both the jacks to high pressure oil pump and vent the system

- Operate pump until a pressure of 350 bar (1st stage ) is reached. Maintain the pressure while two upper nuts are tightened with tommy bar.

- Release the pump pressure to zero.

- In this manner tension all the tie rods in the sequences (1/1, 2/2, 3/3, 4/4, 5/5, 6/6) and measure all the distance ‘L’ and record them as ‘L1’

- Check maker’s reference value ‘L1’-‘L’

- Repeat the same procedure for final tightening to 600 bar (2nd stage)

- Finally measure the distance ‘L’ for each rod and record them as ‘L2’

- Check maker’s reference value ‘L2’-‘L’

- The values should be same if the tie rods are correctly tensioned.