.crankshaft failure

Factors contributing to failure on a crankshaft

Cracks

- Different parts of crankshaft are subjected to different kinds of stresses.

- Cracks weakens crankshaft areas thus leads to failure.

Crankshaft corrosion attack

- Decomposition and oxidation of oil in service

- Contamination of lubrication oil by fuel oil

- Contamination of lube oil by acidic products of combustion (4 stroke engine)

- Possibility of stray electric current entering crankcase resulting electro chemical corrosion

- Oil carrying air bubble with it causes pitting corrosion

Crankshaft twisting or slipping

- If an attempt is made to start the engine when:

- Turning gear is engaged

- Water or fuel accumulation on piston crown.

- Propeller is confined by ice log

- During operation propeller strikes with submerged object

- Seizure of engine component.

- Bottom end bolts failure.

- Crash astern movement.

Misalignment of crankshaft

- Main bearing damaged

- Defective propeller shaft bearing

- Slack or broken tie bolts

- Foundation bolts loosen or fracture

- Engine chocks broken, cracked, or fretted

- Bedplate deformed / damaged

- Hull deformation due to Grounding; Fire

- Weakening of structure due to corrosion

Checking crankshaft deflection/alignment

.crankshaft deflection .deflection .cd .csd

We take crankshaft deflection to make sure that the crank runs and maintain proper balance

Preparation

- Take immobilization permission

- Block starting air valve and put sign

- Propeller clearance

- Tool box meeting

- Risk assessment and work permit done

- Enclosed space entry permit done

- Open crankcase door and ventilate and then check with oxygen analyzer

- Weather is calm

- No operation of loading discharging

- Ship not in drydock

- No maintenance on other engine part

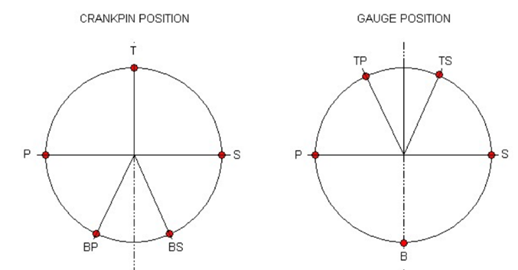

Procedure

Deflections results interpretation

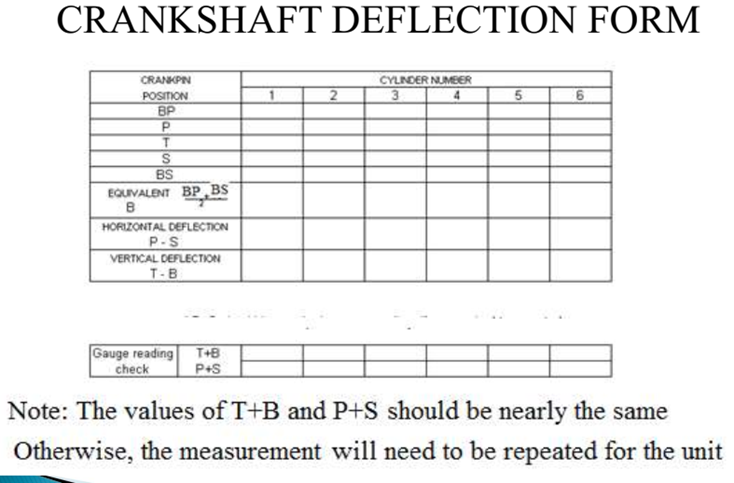

Vertical deflection:

- Difference between top and bottom clearance is the vertical deflection

Horizontal Deflection

- Difference between port and starboard side clearance is the horizontal deflection.

- This value is usually very low.

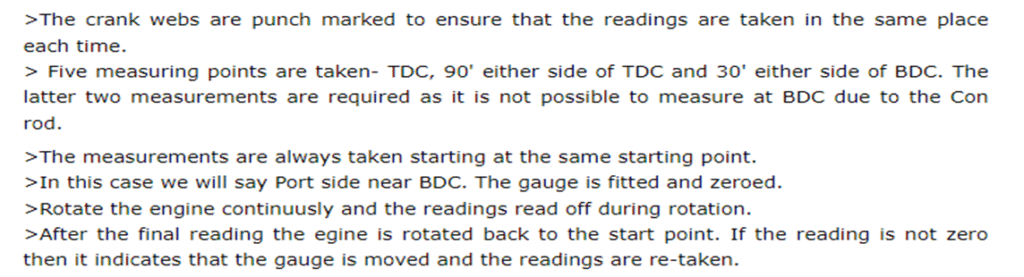

Accuracy checking of deflection reading

The values of T+B and P+S should nearly the same. Otherwise, the measurement need to be repeated for the unit.