The crosshead bearing design in latest engines depends on the pressure of the lube oil supplied to them.

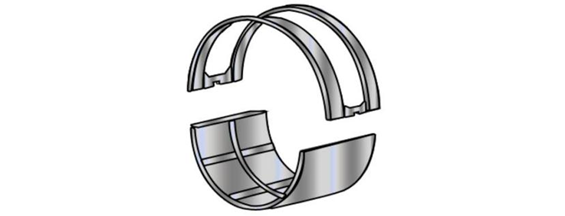

In MAN engine, the crosshead lube oil pressure is same as that of main lube oil system. This is due to the design of the lower shell of the crosshead bearing which has machined wedges to hold oil in them and to support the hydrodynamic lubrication of crosshead pin.

The top shell consists of a cut out part where the piston palm passes and connected to the crosshead pin.

In MAN engine, the lube oil is supplied to the crosshead from telescopic pipe, which is attached to the crosshead face.

IN SULZER engine, the old type model comprises of forked crosshead i.e. the piston rod passes right through the crosshead and is secured underneath with means of piston nut. The crosshead bearing has machined grooves to support oil and lubrication.

In latest SULZER engine, only the lower shell is present which is continuous in nature and the upper bearing housing is lined with white metal.

The oil pressure for crosshead is maintained at 10-12 bar by means of separate crosshead booster pump, which increases the main lube oil pressure.

Material

In MAN engine, the lower shell with grooves is made from SnAL40 and the upper shell is of white metal. While in SULZER, the bearing shell is thin walled made of white metal for high load bearing capacity.