Article link: https://instrumentationtools.com/differential-pressure-transmitter-working-principle/

Question:

Q. Local gauge glass normal but remote level gauge showing high level, cause?

Possible Reasons:

- Leaky bypass valve (pressure regulating valve)

- Defective primary element (primary sensing element-diaphragm)

- Defective transducer

Q. How to blow down DP cell sensing lines?

- Close low pressure sensing line valve.

- Close high pressure sensing line.

- Open bypass valve connecting L.P and H.P side.

- System ready for blowdown.

- Open low pressure side blowdown valve, wait for about 10 seconds, then close it.

- Open H.P side blowdown valve, wait for about 10 seconds, then close it.

Q. Boiler tube plugging:

.btp .boiler tube pluging

Procedure:

- Identify the defective tube when the boiler is pressurized, burner cut out.

- Take permission from office.

- Shut down boiler according to instruction manual, let it cool down, ventilate before entering.

- Whole process may take 2/3 days depending on the severity of tube failure. Take preparation accordingly.

- Prepare enclosed space entry permit, read, and understood by working personnel, have It signed by master.

- Boiler is provided properly sized tube blanks, use them to blank off the tubes.

- Tube needs to be blanked off on both end, clean tube ends.

- Insert tube blanks by hammer, weld if necessary.

- Fill up boiler with feed water and check for leakages under pressure.

- Fire up boiler slowly according to instruction manual.

Control:

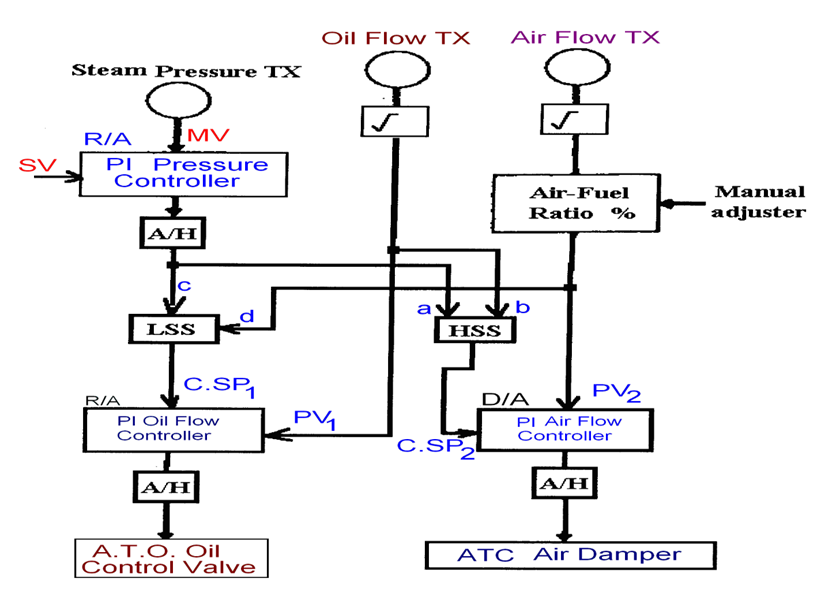

Boiler Auto combustion Control:

.acc .bacc

MV= manipulated value (set point, process value difference)

PV=process value (measured value)

A/H=auto or hand

Description:

Initially, MV=SV, PV1=C.SP1, PV2=CSP2, a ≈ b, c ≈ d.

If steam demand ↑, MV↓

O/P of R/A Master Controller ↑, c↑ , a↑

c > d, d passes through LSS,

so no change in CSP1,

But a > b, ‘a’ passes through HSS,

CSP2↑, PV2↓ wrt CSP2

O/P of D/A Air flow controller ↓

ATC air damper opens more,

Combustion Air flow ↑, d↑,

d passes through LSS since d < c,

CSP1 ↑, PV1↓ wrt CSP1,

O/P of R/A Oil flow Controller ↑,

ATO oil control valve opens more,

Steam pressure restored to SV within a few cycles due to I-action of the Master controller. The control scheme above ensures that air is increased ahead of fuel to prevent fuel-rich condition when load ↑. And similarly, fuel will be decreased ahead of air to prevent fuel-rich condition when load ↓