.sav .starting air valve .sa line

Materials

The body of the valve could be of mild steel, the spindle of high tensile or stainless steel, and the valve and seat could have the contact faces stellite or hardened.

Stellite

It is a range of cobalt-chromium alloys designed for wear resistance. The alloys may also contain tungsten or molybdenum and a small, but important, amount of carbon. Also used as cutting tool.

Starting air line safety:

.starting air line safety .starting air safety .sa safety .sa line safety

Different safety devices are installed on starting air line, in order to prevent explosion.

Bursting Disc It is installed on starting air pipe, between the manifold and the air starting valve. It consists of a perforated disc made of a sheet of materials which will burst in case of excessive pressure secondary to an explosion. Bursting disc is designed in such a way that engine will run even after the disc get ruptured, there is a protective cap on the bursting disc which will cover the hole.

Flame Arrestor Flame arrestor helps to arrest any flame coming out of the cylinder through leaking start air valve.

Relief valve It is affixed on common manifold which shall lift and relieve excess pressure inside the manifold.

Non Return Valve It will not allow the return of any gas from the manifold to the air receiver.

Starting Air SOLAS Requirement:

.starting air regulation .sa regulation

1. For first start arrangement: arrangement for air starting is to be provided so that necessary air for the first charge can be produced onboard without external aid / emergency compressor.

2. For air compressor requirement:

i) Must be fitted with two or more air compressor.

ii) Total capacity of air compressor is to be capable of charging the air receivers within one hour from atmospheric pressure

iii) At least one of the compressors driven independent of main propulsion unit, which acts as emergency air compressor

iv) Capacity not less than 50% of total requirement or approximately divided between them

3. Maximum discharge air temperature: discharge temperature not substantially exceed 930c in service.

4. Air receiver requirements:

i) Two equal capacity of air receiver are provided.

ii) Total air receiver capacity is to be sufficient to provide without replenishment:

→ For reversible engine: not less than 12 consecutive starts of M/E altering between ahead and astern

→ For non-reversible engine not less than 6 consecutive start of M/E in pitch propeller.

Causes of starting air explosion

.sa explosion .sale .sae .airline explosion .air line explosion

.starting air explosion

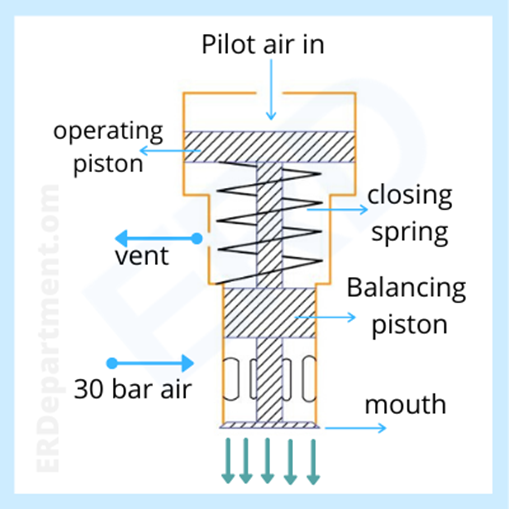

- The main cause of starting airline explosion is leaking or sticking/sluggish/erratic operation of the cylinder starting air valve. Due to the this the hot semi-burned fuel gets forced into the starting air manifold. This is because firing pressures are generally higher than 100 bars as compared to starting air pressures of 30 bar. As more of the hot semi-burned fuel accumulates in the air line, the fuel reaches the explosive limit and spontaneously ignites causing an explosion.

- Also the oil which is discharged from the air compressor to starting airline system. It will deposit as a thin moist film on the internal surface of the pipes but not ready to combustion. If starting air valve leaky hot gas or flame may enter the starting air manifold, and cause starting airline explosion

Indications of an imminent starting air line explosion?

- The starting airline manifold starts to

- Becomes ‘smoky’ due to paint burning

- ‘Blisters’ or ‘bubbles’ form on painted manifolds

- The manifold becomes glowing red hot

- Due to loss of compression pressure, unit may experience high exhaust temperature and power developed will be lower

How to prevent starting air line explosion?

- maintain air start valves

- maintain starting air lines clean

- drain air bottles regularly

- maintain compressor lubrication

- open air line valves slowly

How do you check the cylinder starting air valve for leak?

- Finished with engine

- Get propeller clearance from bridge

- Indicator cocks must be open

- Unit to be tested to be brought to TDC

- Turning gear must be disengaged for test

- Control air to starting air distributor must be SHUT

- Automatic starting air valve must be manually opened

- If start air valve leak, loud hissing sound is heard at indicator valve.

If turning gear is engaged and for some reason the engine turns, the whole turning gear assembly can get ripped off its foundation.

What protective/safety devices are fitted to overcome starting air line explosions.

- Relief valve

- bursting disc

- flame trap

- Non return valve

Studies have shown that most occurrences of starting air line explosions took place during manoeuvring than at sea, why?

- Because only during manoeuvring we operate the starting air valve so during this time the possibility of sticking or sluggish operation of the v/v is high.

- Also during the manoeuvring air is present in the manifold where at sea there is no air in the manifold.