.De-tuners .detuner .detuner .dt

The natural frequency of vibration is always present in engines, but the effect can be dangerous when the vibration frequency reaches high levels.

This happens when the natural frequency of vibration from an external source integrates with the engine vibration or when there are out-of-balance forces generated inside the engine

This can result in severe damage to the marine engine’s internal moving parts, cracks in the structure, loosening of bolts and securing and damage to bearings. Vibration of Marine Engines is mainly due to- Axial and Torsional Vibration or combination of both.

In order to reduce such vibrations, different methods and systems are used, which includes de-tuners, dampers thrust pads, chokes

De-tuners are used to alter the frequency of the vibration of the engine thus reduce the vibration of the engine.

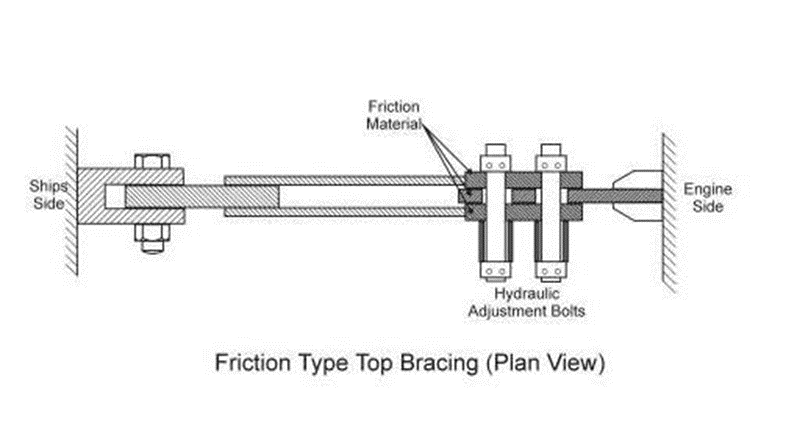

Frictional type Bracing is one such de tuner Normally fitted on the top of the engine which increases the stiffness and raises the natural frequency beyond the working range.

Friction type bracing is one of the common types used for 2 stroke slow speed marine engines.

The working of these type of bracing depends upon the friction between the pads that brace the engine at the top so that the resonances occurs above the speed range of the engine.

Last but not the least, the tension on the bolts must be regularly checked along with the inspection of the structure for any cracking especially around the welds.

Axial Damper: The Axial damper is fitted on the crankshaft of the engine to dampen the axial vibration which is generated by the shaft in forward and aft directions, parallel to the shaft horizontal line.

It consists of a damping flange integrated to the crankshaft and placed near the last main bearing girder, inside a cylindrical casing. The casing is filled with system oil on both side of flanges . This oil provides the damping effect.

When the crankshaft vibrates axially, the oil in the sides of the flange circulates to the other side through a throttling valve, which gives a damping effect.

high temperature alarm and pressure monitoring alarms located on both sides of damping flanges. They give alarm if one side oil pressure drops more than the set value as a result of low LO supply or sealing ring failure.

Torsional Damper: twisting phenomenon in the crankshaft spreads from one end to the other due to uneven torque pulses coming from different units of the engine

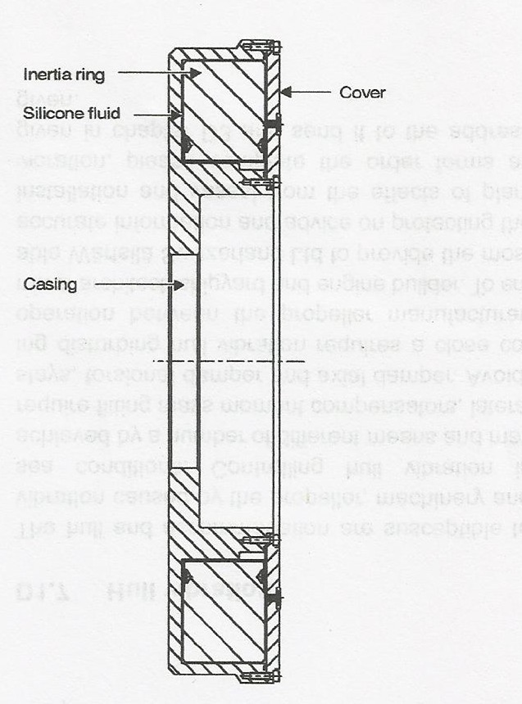

The most famous type of torsional damper used on ship is Viscous type dampers, which consist of an inertia ring

This ring is added to the crankshaft and enclosed in a thin layer of highly viscous fluid like silicon. The inertia ring is free to rotate and applies a lagging torque on the crankshaft due to its lagging torsional motion.

When the crankshaft rotates, the inertia ring tends to move in radial direction but the counter effect is provided by the silicon fluid which damp the vibration.