.hv safety

.hv

.high voltage safety

Personnel who are required to routinely test and maintain HV equipment should be trained in the necessary practical safety procedures and certified as qualified for this duty.

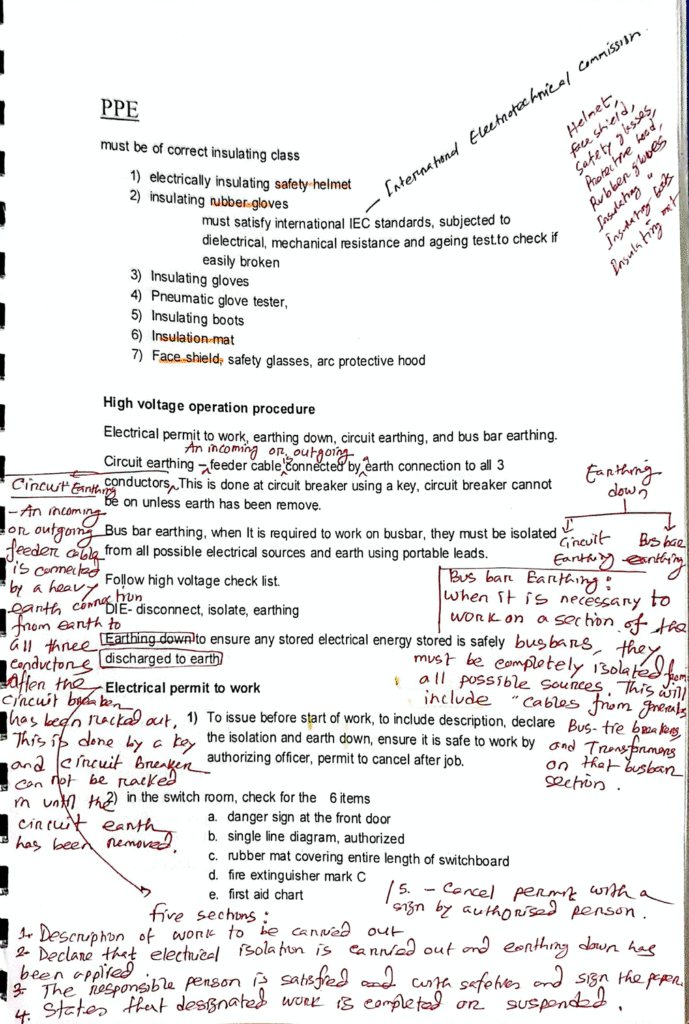

- Approved safety clothing,

- Highly insulating safety gloves

- footwear,

- eye protection and

- hard hat should be used where danger may arise from arcs, hot surfaces and high voltage etc.

Safety equipment should be used by electrical workers includes insulated rubber gloves and mats.

Safety equipment is tested regularly to ensure it is still protecting the user.

A insulated material or rubber mat can be used as a dead front of all electrical installations and equipment.

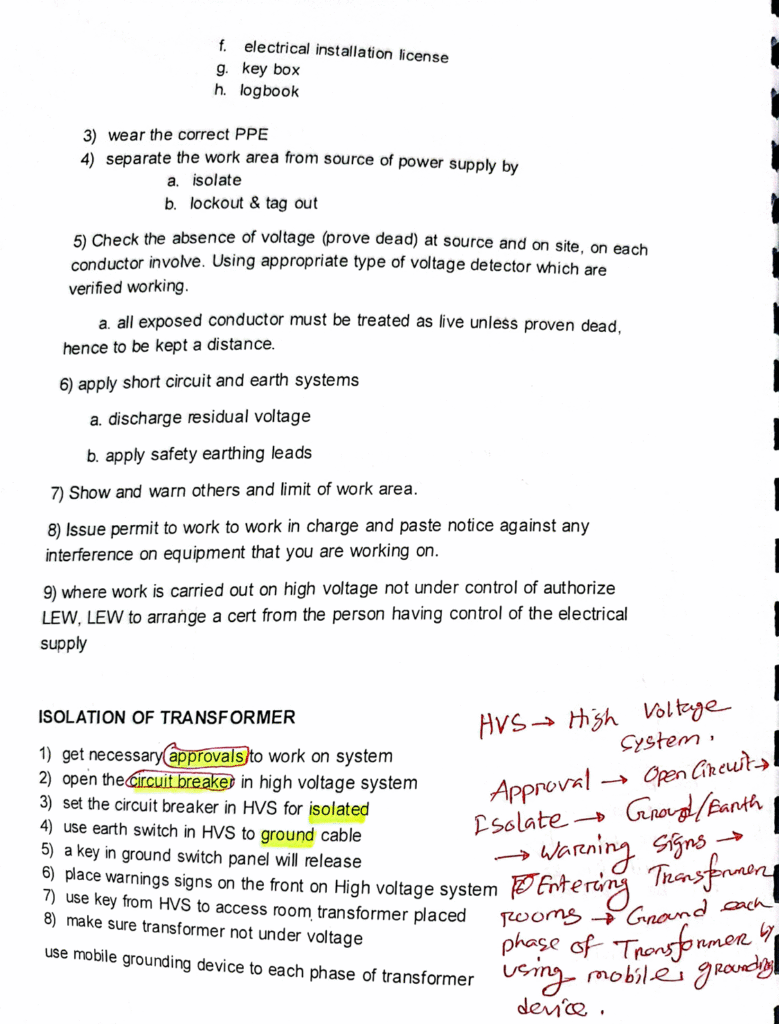

The access to HV switchboards and equipment must be strictly controlled by using a permit-to-work scheme and isolation procedures together with live-line tests and earthing-down before any work is started. The electrical permit requirements and procedures are similar to permits used to control access in any hot-work situation, e.g. welding, cutting, burning etc. in a potentially hazardous area.

What Are The Additional Safeties On High Voltage System?

> HV circuit breakers either air, gas or vacuum breakers.

> To minimize the size of earth fault current, neutral earthing resistor is using in HV system. Better insulating material like Micalastic is used.

> HV equipment are well designed to have an insulation life of 20 years

> Special relays are provided for overall circuit protection of HV circuit

> Earthing down is essential for HV maintenance which should be declared in Electrical Permit to Work.