.impingement

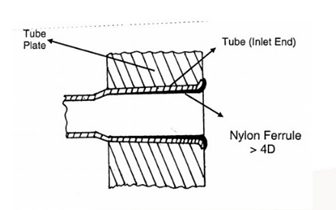

Seawater flowing into the heat exchanger tubes at higher velocities tends to remove the thin protective film adhering to the base metal of the tube wall. This protective film is peeled and allow further corrosion of the tube wall. Due to this continuous process the tube wall is gradually thinned, and the tube-to-tube plate joint is weakened and ultimately fails or the tube walls just beyond the tube plate is perforated. This type of erosion is termed “Impingement Attack” or inlet end attack or bubble attack. This attack is usually taken place in a length of 4 x diameter of tube from the inlet side.

Causes:

- Higher velocity of cooling water

- turbulence flow give rise to Impingement Attack

- Entrained air bubbles tend to accelerate this action, as do suspended solids.

- Impingement attack is related to cavitation damage, and has been defined as ‘localized erosion-corrosion

Remedy:

- the velocity of the cooling sea water should not exceed 4 m/sec or fall below 1m/sec.

- If it is more than 4m/sec, then it will aid in impingement attack

- if it is below 1m/sec, then salt and other solid particles will tend to settle on the tube surfaces, which in turn will form into small electrolytic cells resulting in the erosion of the tube material.

- turbulent flow is NOT preferred in the shell and tube heat exchangers.

- To maintain a proper laminar flow, the design of the header and fitting of the zinc anodes are important, care must be exercised that the zinc does not interfere with or add to the turbulence to the fluid within the header

- the tube inlet ends are fitted with nylon ferrules to protect tubes of large heat exchangers

Chemical handling onboard:

.chemical handling

.chem handling

- Make sure all crew members have easy access to Safety Data Sheets and that these are kept up to date.

- Ensure all chemicals are stored safely – and, if possible, restrict access to authorised people.

- Provide specific training courses for crew members using or handling hazardous substances.

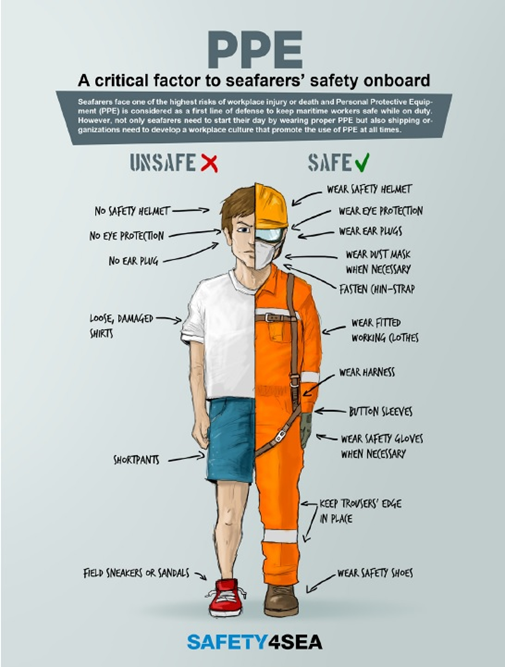

- Fully assess tasks before procuring personal protection equipment (PPE) and introduce processes to prevent improper PPE being used.

- Make sure all crew members are aware of the risks associated with chemicals as well as your vessel’s first aid steps.

- Make sure suitable first aid measures in place.

Article link: https://oceantimemarine.com/what-to-do-with-chemicals-on-board-your-vessel/

Storage

- DO store chemicals in a suitably contained safe area that is well marked. Class 8 (corrosive) and class 5 (oxidisers) for example should be in well segregated areas.

- DO store chemicals in containers kept at single level so ingredients cannot mix

- DO keep chemicals below eye level to avoid accidental spillage over your face

- DO keep the lids on chemical containers on tight and secure so the contents cannot mix or spill if you are moving the product

- DO make sure the chemical is well labelled and can be easily identified.

- DO NOT mix chemicals. This can result in serious harm including death.

- DO NOT mix drum pumps between chemicals as a bad reaction may occur.

- DO NOT put chemicals into unmarked containers.

- DO NOT use old food or drink bottles as accidental ingestion can occur and will cause serious internal injuries or death.

Directions for use

- DO wear the correct PPE (personal protection equipment) as recommended on the material safety data sheet (MSDS) and the label. This may include goggles, gloves, respirator, suits and boots.

- DO read the label on the container as this gives usage and mixing directions. The container may have POISON or a Dangerous Goods Diamond with Class designation as to what type of hazard it presents on it.

- DO make yourself familiar with the MSDS. MSDS is provided with every container and provides information about that product such as description of the chemical, specifications, and safety and emergency instructions.

- DO mix or dilute the chemical to the supplier’s specifications only. Mixing an acid based chemical with a chlorinated chemical will result in a deadly chlorine gas being emitted.

- DO make sure cleaning is completed before leaving the area to prevent accidental skin contact with the chemical.

First Aid

- know where your first aid station is located

- read and be familiar with first aid instructions about the specific chemical being used which can be found on the label and MSDS sheet

- be familiar with the location of eye wash facilities around the vessel. In the event of a splash in the eyes you need to be able to automatically find the closest water source.

- a spill to the eyes should be washed under cool running water for 15 minutes

Emergency

In case of an emergency: know where emergency equipment, such as fire extinguishers, hoses and eyebaths, are located know what the vessel’s emergency procedures are and how to fulfil that task.