—

*To: Third Engineer (3/E)*

*From: Chief Engineer (C/E)*

*Subject: Generator Major Overhaul Instructions*

*Date: [Insert Date]*

—

*Objective:*

To perform a comprehensive major overhaul of the ship’s generator to ensure optimal performance and reliability.

—

*Instructions:*

1. *Preparation:*

– *Safety First:* Ensure all necessary personal protective equipment (PPE) is worn, including gloves, safety glasses, and hearing protection.

– *Isolation:* Isolate the generator from the electrical system. Lock out and tag out (LOTO) procedures must be followed strictly.

– *Work Area:* Clear the work area of any unnecessary items and ensure adequate lighting and ventilation.

2. *Documentation:*

– *Manuals:* Refer to the generator’s operation and maintenance manual for specific guidelines and tolerances.

– *Checklists:* Use the provided maintenance checklists to ensure no step is missed.

– *Record Keeping:* Document all findings, measurements, and parts replaced in the maintenance log.

3. *Inspection:*

– *Visual Check:* Inspect the generator for any visible signs of wear, damage, or oil leaks.

– *Connections:* Check all electrical and mechanical connections for tightness and integrity.

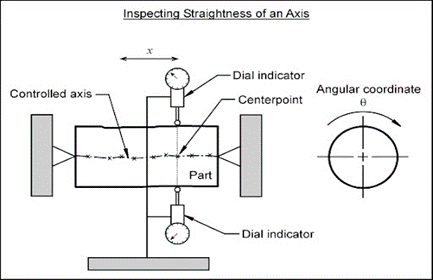

– *Alignment:* Verify the alignment of the generator and prime mover (e.g., engine or turbine).

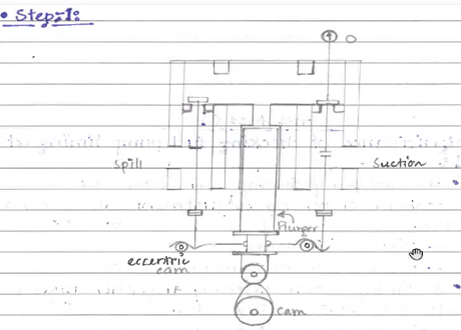

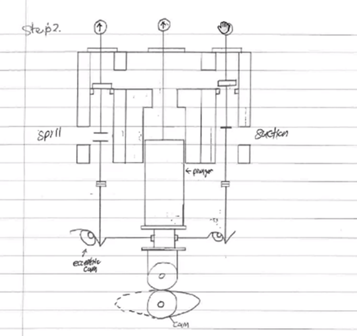

4. *Disassembly:*

– *Components:* Carefully disassemble the generator, taking note of the order and orientation of parts.

– *Cleanliness:* Keep all removed parts clean and organized. Use clean containers to store small components.

– *Rotor and Stator:* Pay special attention when handling the rotor and stator to avoid damage.

– *Mechanical Parts:* Disassemble mechanical components such as pistons, cylinders, connecting rods, and crankshaft if applicable.

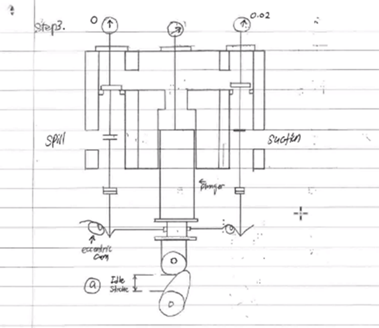

5. *Inspection of Components:*

– *Bearings:* Inspect bearings for wear or damage. Replace if necessary.

– *Windings:* Check the windings for insulation resistance and signs of overheating or damage.

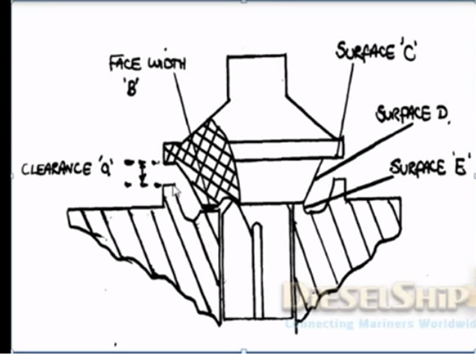

– *Slip Rings/Commutator:* Examine the slip rings or commutator for wear, scoring, or pitting. Clean or replace as required.

– *Cooling System:* Inspect the cooling system components, including fans, heat exchangers, and ducts.

– *Mechanical Parts:*

– *Pistons and Cylinders:* Check pistons and cylinders for wear, scoring, or pitting. Measure clearances and replace if out of tolerance.

– *Connecting Rods:* Inspect connecting rods for cracks or wear. Check the alignment and replace if necessary.

– *Crankshaft:* Examine the crankshaft for wear, cracks, or misalignment. Measure journal diameters and check for any signs of damage.

6. *Cleaning:*

– *Degreasing:* Clean all parts using appropriate solvents and degreasers.

– *Drying:* Ensure all parts are thoroughly dried before reassembly.

– *Ventilation Paths:* Clean all ventilation paths and cooling fins to ensure efficient heat dissipation.

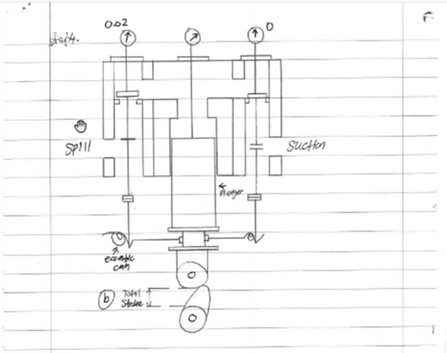

7. *Reassembly:*

– *Lubrication:* Apply the recommended lubricants to bearings and other moving parts.

– *Torque Specifications:* Use a torque wrench to tighten bolts and nuts to the specified torque values.

– *Alignment:* Recheck the alignment of the generator and prime mover during reassembly.

– *Mechanical Parts:*

– *Pistons and Cylinders:* Carefully reassemble pistons and cylinders, ensuring correct orientation and clearance.

– *Connecting Rods:* Reassemble connecting rods with the correct torque settings and alignment.

– *Crankshaft:* Reinstall the crankshaft, ensuring proper alignment and lubrication.

8. *Testing:*

– *Pre-Startup Check:* Perform a pre-startup check to ensure all connections are secure and all components are correctly installed.

– *Startup:* Start the generator and monitor it closely for any abnormal noises, vibrations, or readings.

– *Load Test:* Perform a load test to ensure the generator operates correctly under load conditions.

9. *Post-Overhaul:*

– *Final Inspection:* Conduct a final inspection to verify the generator is operating within the specified parameters.

– *Documentation:* Update the maintenance records with all work performed, including parts replaced and test results.

– *Report:* Prepare a detailed report on the overhaul process, highlighting any issues encountered and solutions implemented.

—

*Notes:*

– If at any stage you encounter issues beyond your expertise, do not hesitate to consult with senior engineers or the manufacturer’s technical support.

– Ensure all replaced parts are documented and properly disposed of according to environmental regulations.

—

*Chief Engineer Signature:*

*Date:*

—

Please proceed with the overhaul, following the instructions diligently. Ensure all safety protocols are adhered to, and maintain a high standard of workmanship.

—

If you need any further assistance, feel free to reach out.

Best regards,

[Chief Engineer Name]

—