Article link:

Sketch:

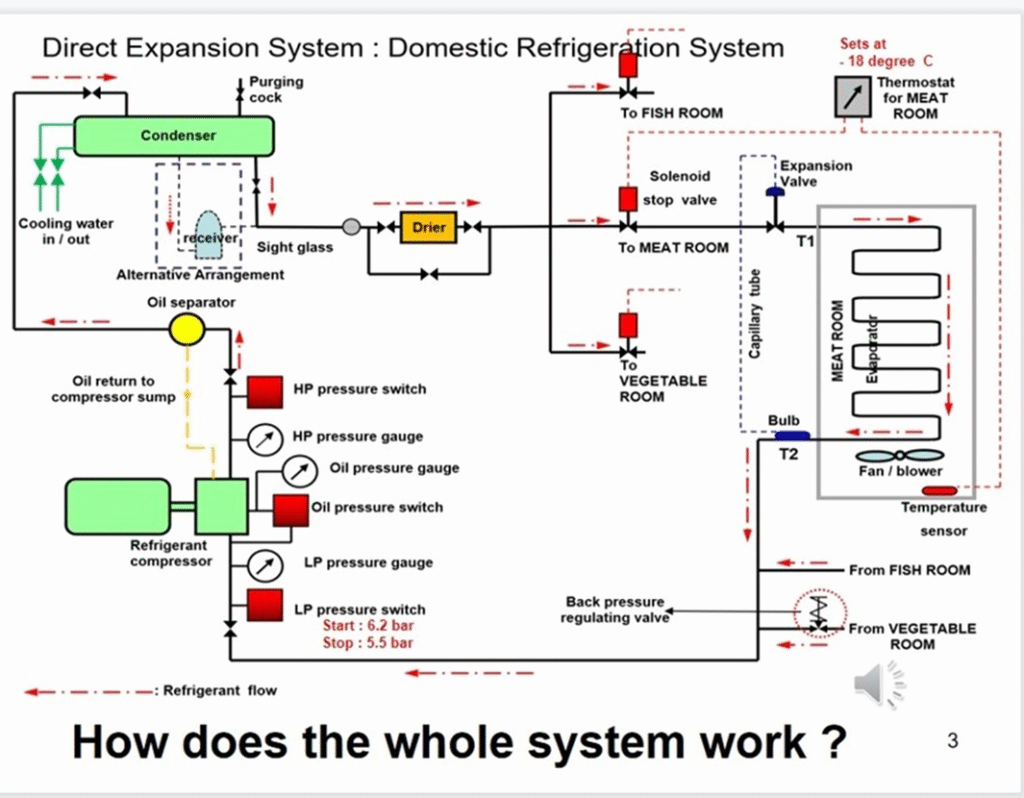

Direct expansion system:

.refrigeration system

→ evaporator coil situated inside the space to be refrigerated.

→ no duct and piping required

- The evaporator coil extracts the heat from the air inside.

- The compressor draws low pressure refrigerant vapour and delivers the high pressure refrigerant vapour through an oil separator to the condenser.

- The condenser liquefies the refrigerant.

- The liquid refrigerant from the condenser passes through the filter dryer, solenoid valve and thermostatic expansion valve to the evaporator.

Checks

Before starting the refrigeration plant,

- Check the oil level in the crank case of the compressor.

- Insufficient oil wears down the components.

- In extreme cases, it may lead to seizure of the compressor.

- Check whether the cooling water inlet and outlet valves to the condenser are open.

- Insufficient flow of cooling water results in improper condensation which in turn increases the compressor discharge side pressure.

- Open the compressor outlet valve, condenser inlet valve, receiver outlet valve, filter drier inlet valve and outlet valves.

- Check whether power supply is available to the compressor motor.

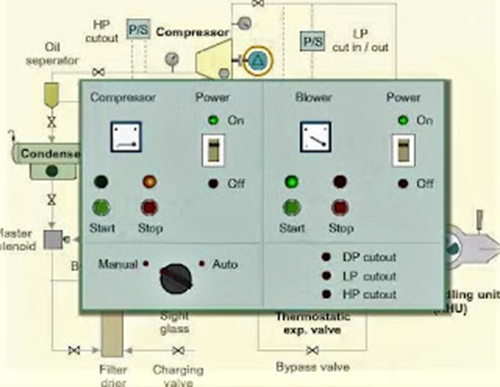

- Ensure the compressor is in manual mode.

During start

- Open the compressor inlet valve by half a turn and start the compressor.

- Open the compressor inlet valve slowly to fully open position.

- Change the operation of the compressor to automatic mode.

- Check the amperage of the compressor.

During operation:

- Check the compressor suction, discharge, and oil pressure.

- Inspect the compressor unit and check for any abnormality and vibration.

- Check the compressor oil level and check whether the oil returns from the oil separator to the crankcase

During auto Stopping:

- As the temperature reaches the set value, the thermostatic switch will cut off the compressor.

- The blower will continue to run.

- When the air temperature increases, the compressor will cut in.

To shut down for longer duration:

- To shut down for prolonged period, close the condenser liquid receiver outlet valve.

- The liquid refrigerant is collected inside the condenser receiver and the compressor stops due to low pressure.

- Shut the refrigerant line valves.

- Shut the condenser cooling water inlet and outlet valves.

- Switch off the power supply.

| AIR CONDITIONING SPECIFICATION | |

| SPECIFICATION | AIR CONDITIONING PLANT |

| Refrigerant | R-404 A |

| Cooling method | direct expansion system |

| Heating method | steam coil |

| Humidification | steam spray |

| Compressor | four cylinder, reciprocating |

| Condenser | horizontal shell & tube type |

| Main power source | 440 v AC, 60 Hz, 3 phase |

| Control circuit power source | 220 v AC, 60 HZ, 3PHASE |