.removal broken tie rod .btr .broken tie

Safety precaution:

- Permission must be granted to immobilize the engine

- Propeller clearance to be obtained

- Block start air mechanism and shut start air. main valve

- Turning gear engaged & indicator cock must be opened

- Stop L.O pumps and shut all V/V’s

- Crankcase should be treated as enclose space entry permit to work combined with a risk assignment should be done.

Procedure

- If breakage does occur, engine can be operated with reduced load for a limited period

- Position of fracture will dictate how broken pieces are removed.

- If bolt broken at mid length, lift out the top half, remove the bottom nut

- Feed a loop of braided wire cable (about 7mm diameter) down the tie bolt tube

- When it emerges at bottom a supporting piece can be fitted to the wire

- This enable broken tie bolt to be withdrawn.

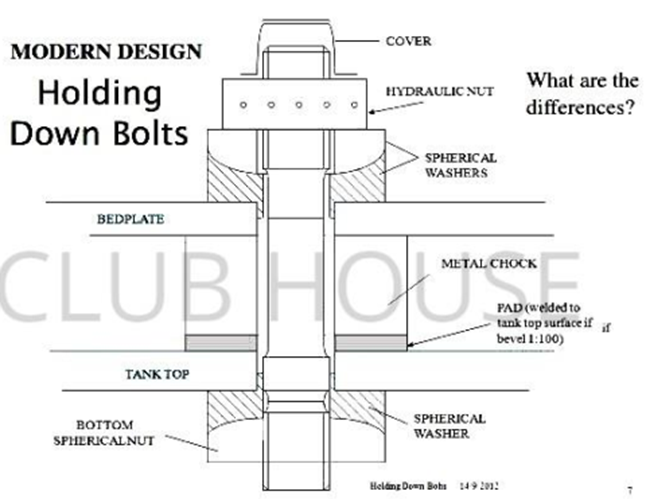

Holding down bolt

.holding down bolt .hdb