.safety valve inspection .bsvi .safety valve survey .bsvs

Valve & Seat

- Check visually for any sign of scoring (scratches), pitting etc

- Carry out a ‘mating check’ between valve and seat using Prussian blue or engineers’ blue

- A continuous ring indicates there will be no leak between valve and seat

Spindle

- The spindle is always under compression during service. As such, it is prone to get bent.

- Checks must be done to ensure its ‘straightness’ or ‘true-ness’

Spring

- Visual inspection carried out for excessive pitting due to rusting. The common spring material is carbon steel which gives the right stiffness but is prone to rusting. (FYI, stainless steel has very high stiffness)

- Due to ‘skewering effect’, springs tend to slant to one side over time. Check for perpendicularness.

- Due to prolonged compression, spring tends get ‘shortened’ .Free length (after usage) > 95% of natural length (when new)

Valve Body

- Look for signs of corrosion inside/outside of valve body

- Check for scale deposits build-up inside body

Drain Pipe

– Ensure drainpipe is clear by blowing with air

What should be the capacity of each safety valve? (For guidance)

Answer: Each safety valve should match the maximum steam generation rate of the boiler

Why do you set the second safety valve slightly higher than the first valve?

Answer: If the first safety valve fails to lift, then the second safety can act as a back-up.

Then why can’t you set both the safety valves equally?

Answer: If both the safety valves lift together, then the blowdown will double which is not economical due to excessive loss of steam pressure.

What is the difference between Design Pressure (DP) and Maximum Allowable Working Pressure (MAWP)?

Answer: In most cases, they are of the same value.

However, during newbuilding, if you have sourced for a boiler with DP 12 bars but ship’s heating coils designed to withstand 10 bars, then the ship’s boiler can only operate to a maximum of 10 bars which is the MAWP.

DP is no longer valid on the ship.

Your boiler has a design pressure of 10.0 bars. You would like to operate your boiler at maximum working pressure.

- What can be the settings of your safety valves?

Answer: Maximum settings of safety valves are about 9.7 bars & 10.0 bars maximum.

The Maximum Working Pressure is usually 10% lower than the safety valve setting. MWP is 9.0 bars.

State the operational problems encountered in service for the boiler safety valves.

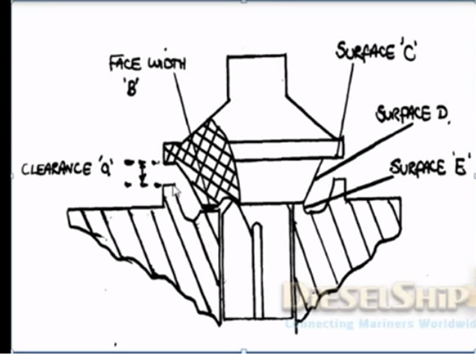

- Due to wear between valve and seat, lip clearance reduces and causes increase in blowdown

- Drain passage getting choked causing water accumulation and hence prevent smooth valve operation

- Spring tends to rust and cause valve seizure

- Valve spindle bending due to constant compression (can cause valve to have erratic/sluggish operation)

What is the purpose of lip clearance?

Answer: The purpose of lip clearance is made for valve lid to sit completely on seat or if clearance is zero then the valve lid cannot seal or close completely. It is measured by lead ball kept between lip and assemble the valve properly.

During inspection, if you find the valve and/or seat is badly scored, how would you rectify the defect?

In case the mating surfaces between the valve and seat are badly scored, they can be rectified by grinding.

Valve: Can be grinded against a cast iron plate, using a fine grained carborundum paste stirred in kerosene.

Seat: The seat in the valve body can be grinded in the same way by using a cast iron rod of suitable size. Use ‘Prussian Blue’ to do the mating surface check

Never use the valve itself when grinding the seat. This will increase the wear of valve and seat.

What are the routine checks carried out to ensure the proper operation of the safety valves?

- Check for any water/steam seepage from drainpipe fitted to safety valve. Drainpipe must be dry

- Check escape pipe if it is hot due to steam leakage (use infra-red thermometer)

- Check at funnel for any sign of steam emission

- If there is a slight leakage, manually operate the easing gear

You are the Senior Engineer onboard a tanker. You receive instruction from charterers to maintain your steam pressure at maximum 8.0 bars to prevent overheating of cargo. What is your action?

- In oil-fired boilers, I would set the automatic burner to cut-out at 8.0 bars.

- In waste heat recovery systems, I would set the ‘steam dump’ controller at 8.0 bars

- Above actions will maintain the steam pressure at a maximum of 8.0 bars

How to check the previous setting of the safety v/v

Answer: by checking the compression ring.

how to check the spring is perpendicular?

answer: by engineer square or the L scale.

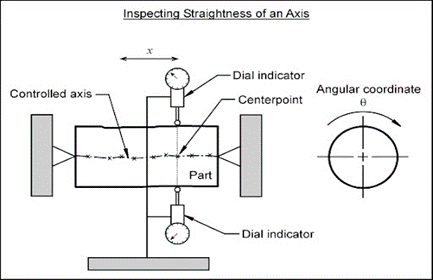

How do you check the straightness of a spindle?

Answer: mount in the lathe machine and slide the dial gauge axially with the spindle.