.stp .sewage treatment plant

Overview of Sewage Treatment Plant on Ships

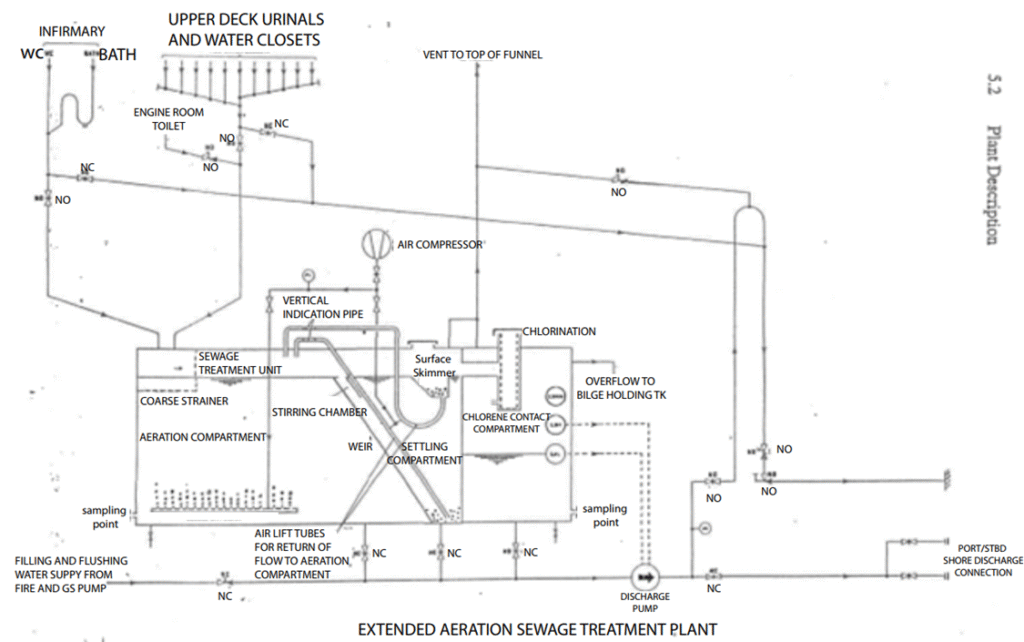

Sewage Treatment Plants (STPs) are crucial systems on ships for processing and treating wastewater before discharge. Proper maintenance and regular checks are essential for ensuring the STP’s efficient operation, compliance with environmental regulations, and prevention of system failures.

Routine Checks and Maintenance

Daily Checks

- System pressure: Verify it’s within specified limits

- Air lift return: Ensure proper flow through clear plastic pipes

- Sludge content in aeration tank: Should not exceed 200 mg/liter

- Chlorination levels: Maintain between 1-5 ppm

Weekly Checks and Tasks

- Add bio-pac (aerobic bacteria) to enhance efficiency

- Measure Biological Oxygen Demand (BOD): Should not exceed 25 mg/liter

- Check sludge content using manufacturer-specified methods

Other Periodic Checks

- Inspect internal coating for damage (cracking, blistering)

- UV lamp replacement (if applicable)

- Verify high and low-level limit switches for discharge pumps

- Ensure stand-by sewage discharge pump is on auto mode

Key Maintenance Points

- Back flushing procedure for clearing blockages

- Proper use of cleaning chemicals as per manufacturer recommendations

- Regular inspection and cleaning of tanks (with safety precautions)

- Monitoring and adjusting chlorination or UV disinfection systems

Safety Precautions

- Gas testing before tank entry (use dragor tube)

- Proper Personal Protective Equipment (PPE) when entering tanks

- Disinfection procedures after maintenance work

- Proper hygiene practices for personnel involved

Troubleshooting and Common Issues

- Blockages in sewage lines

- Excessive sludge buildup

- Inefficient bacterial action

- Equipment malfunctions (pumps, switches, etc.)

Record Keeping and Documentation

- Maintain logs of all checks and maintenance activities

- Document test results and any corrective actions taken

- Keep records of chemical usage and bio-pac additions

Environmental Compliance

- Understand and adhere to MARPOL Annex IV regulations

- Ensure effluent meets or exceeds MEPC 159(55) standards

- Be aware of local regulations in different operational areas