.sulzer fuel p/p timing .sfpt .sulzer timing

procedure of checking the timing for valve control type fuel pump

Initial preparation and safety checks

Ø Tool box meeting carried out.

Ø Arrange appropriate tools and instruction manual to keep ready

Ø Take permission to immobilize the engine

Ø After permission granted carry out proper shutting down procedure of M/E

Ø Starting air system and starting mechanism to be isolated

Ø Open indicator cocks and engage turning gear

Ø Propeller clearance taken

Ø Shut off fuel oil supply

Ø Any setting to be done refer to instruction manual

Ø VIT hand setting lever is set to zero. Fuel lever is set to maximum with engine set run ahead

Ø Pump is isolated and drained

Ø Remove cover, spring and delivery valve above the plunger

Ø Remove the cover and spring above the suction and spill valve

Procedure for checking timing of pump

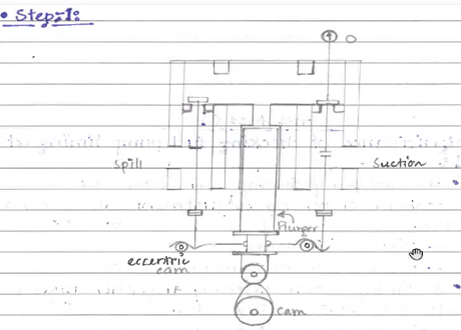

Step1

· Turn the engine in ahead direction until pump plunger is at top dead centre

· Fit dial gauge to the suction valve

· After tensioning the gauge set it to zero

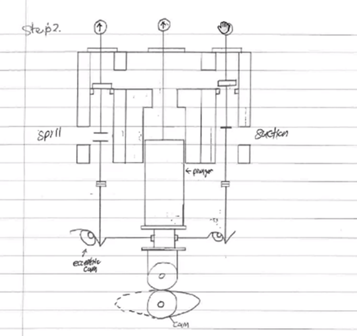

Step 2:

- Turn the engine in astern direction until pump roller is on cam base

- Fit dial gauge to the plunger and spill valve

- After preloading the gauge set them to zero.

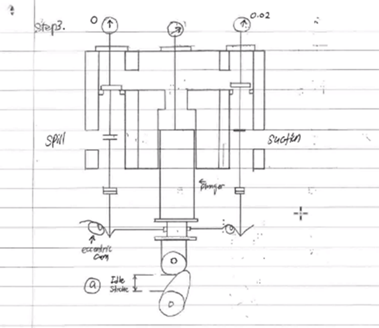

Step 3

· Turn the engine in ahead direction until the suction valve gauge reads 0.02 mm

· At this point suction valve is just closing and fuel delivery to begin

· Note the plunger dial gauge reading (a) and crank angle

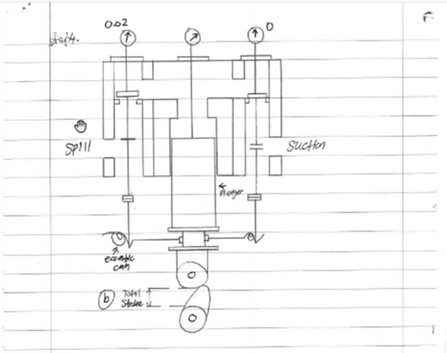

Step 4

· Continue to turn the engine in ahead direction until the spill valve gauge reeds 0.02 mm

· This indicates that the spill valve is just opening and fuel delivery will stop

· Note the plunger dial gauge reading (b) and crank angle

· Effective plunger stroke= b-a

· Maximum admissible deviation is 0.2 mm

· Check all values with setting table.

c. Safety checks after adjustment

The following point to be checked

- The zero position in the load indicator and setting shield on the fuel pump must be coincide.

- When the pump is manually cut out there must be some clearance exists between the roller and the cam peak( 0.5mm minimum)

- Safety cut out checks of the pump should be done after every resetting and after every major overhaul.

- When the safety cut device is activated the suction and spill valve should lift from the seat thus ceasing the fuel injection.

- This is important to ascertain that engine can be shut down / stopped positively at any time due to emergency and engine does not get overloaded.

- When the shield position is zero then suction and spill valve will never be closed at same time in an individual pump.ie when one valve is closed other valve must be open so that the fuel injection excluded this determines the effective delivery stroke is zero.